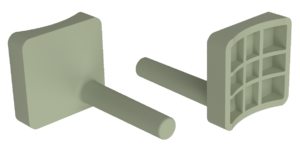

Custom Window Holder

Reproduction of obsolete parts is becoming a common practice with the advancement of 3D Printing and Prototyping methods.

Over time, the current product was degrading due to heat and UV exposure causing them to fail. These parts were no longer being manufactured by the OEM company so replacement parts were obsolete and impossible to obtain. The existing parts were used to reverse engineer a design that could replicate the function while maintaining the structural integrity, thermal property requirements, and cost.

Once the design was created, prototypes were quickly 3D Printed to test for form, fit, and function. The material used to produce the prototypes was tested with repeated cycles and found to be effective. While this part could replicate the originally designed part as is, it would become less cost efficient since more than several hundred windows would require the replacement part. The new custom window holder was designed more efficiently to reduce cost while utilizing a material that will hold up to the physical and environmental factors that it will be exposed to.

To cost effectively produce higher quantities, the injection molding process was used. With a vast variety of materials to choose from, the environmental requirements were used to select the appropriate material.

Parts were successfully produced and installed to eliminate the prior issues that were present with the existing window part.