Replacement Of Obsolete Parts

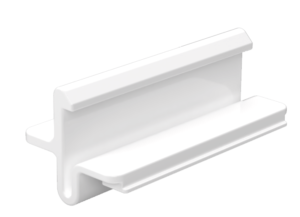

What do you do if a part you have is obsolete and no longer available from the Original Equipment Manufacturer (OEM)? You 3D Print it. Yes, in some cases 3D Printing is used to replicate and produce obsolete parts that are no longer produced or available from the original manufacturer. That is exactly what happened with a recent project where the client had parts for their windows that were breaking and no longer available to replace. The first step in the design process was to reverse engineer the existing part to come up with a 3D design that would be used to create the replacement parts. In this case, design modifications were performed to strengthen the part from its original form. Once the design was completed, a quick prototype was made using our house 3D Printing/Additive Manufacturing process. Once the design was validated, several options were evaluated to produce the batch of final parts that the client requested. One option was to Injection Mold the parts. This requires making a mold. The second option was to utilize 3D Printing to produce the parts. Some benefits of using 3D Printing to produce the replacement parts include shorter lead times and cost savings over injection molding. Based on the requirements of the project, 3D Printing was selected as the best option for this project. Parts were made with UV resistant material so that they will hold up to elements that they would be exposed to.

Building these parts on-demand has several benefits to the end user and allows for no minimum order quantity and inventory.

Developing Ideas From Concept To Product®

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Connect with us on Twitter, Facebook, Instagram, & LinkedIn today.