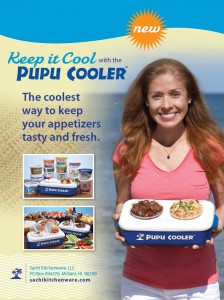

Pupu CoolerTM

With a conceptual design already outlined, Sachi Kitchenware needed to go from a conceptual design to a fully functional and manufacturable design. In searching for companies to help him develop his idea, the challenge became finding someone with expertise not only in prototyping, but designing his concept for the Injection Molding process.

Using parametric design/engineering software, we were able to create their initial concept and make modifications relatively easy during design review processes. Once a final design was approved, prototype parts were created using 3D Printing to quickly evaluate the design. Compared to conventional fabrication/manufacturing methods, the cost of using the 3D Printing process was over 400% less and was done in 4-5 days compared to 3-4 weeks. This lower cost solution allowed for slight design modifications without the cost of re-tooling or re-making the parts.