Some of the past projects include various mechanical and industrial designs that range from Aerospace to consumer products, architectural fittings, medical devices, industrial sheet metal, food containers, electronics, and replacement OEM parts.

Production parts were injection molded, thermoformed, and stamped from a variety of materials such as plastic, silicone, rubber, and aluminum.

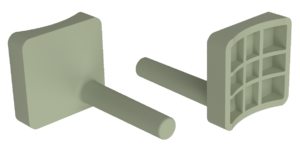

Custom rubber cover plug

Custom cover plug for hotel door locking system. High temperature and oil resistant rubber.

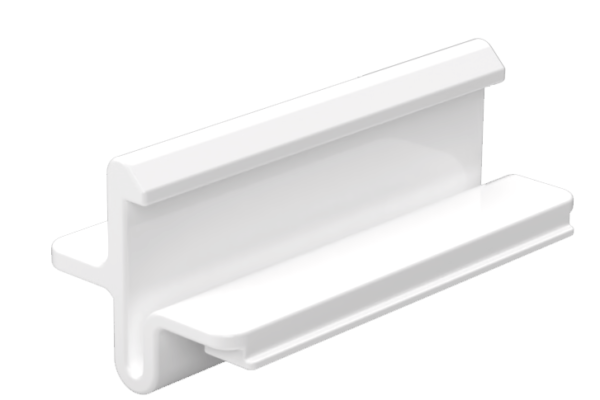

Replacement window latch

Replicated window latch replacement for obsolete parts

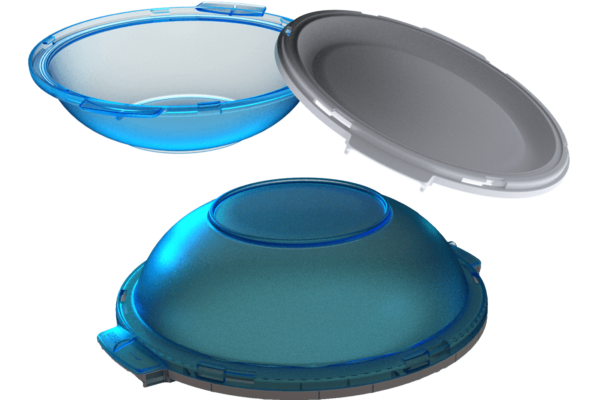

Multi Dish Bowl & Plate combo

Multi Dish Food ware

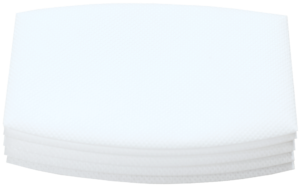

InsightPPE

KN95 Mask Filter Inserts for protection against airborne viruses.

Herbavore

Ergonomic and interchangeable pruning shears

Bottle Buddy

Bottle Cap for children

Pacific Ocean Dreams

Sand Anchor to safely secure umbrellas and tents at the beach

Medical Device

Wireless medical monitoring device

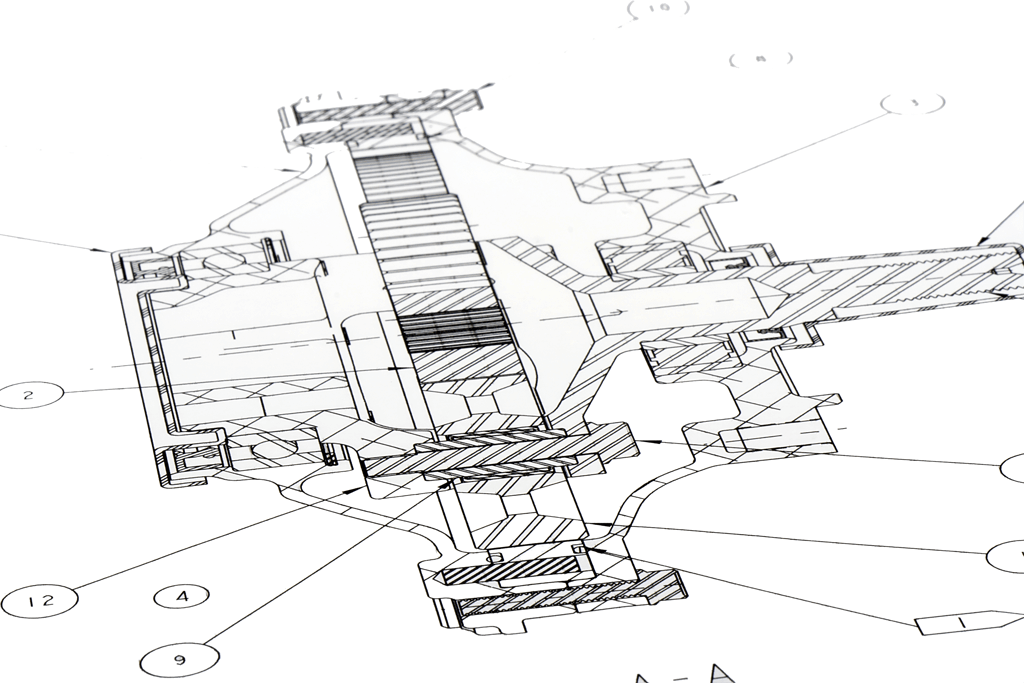

Manufacturing Drawings

Assembly instruction diagrams

Design documentation

Parts List generation

Food Container Design

Custom Shave Ice cup design

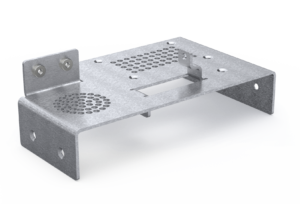

Custom Sheet Metal part

Custom Sheet Metal part for electro-mechanical assembly

Custom Lure Designs – Atama Lures

Custom Lure Plug design for silicone mold and casting resin production

Electronic Wearable Tech

Electronic Wearable Tech product for sensing, monitoring, and data capturing

Condominium Association

Injection Molded custom window holder

High tensile strength + high thermal properties

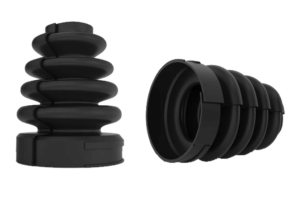

Anuva Company

Quick and Easy Change CV-boot kit

Smiley Rides

Interactive dental products designed for children to promote life long healthy oral hygiene habits

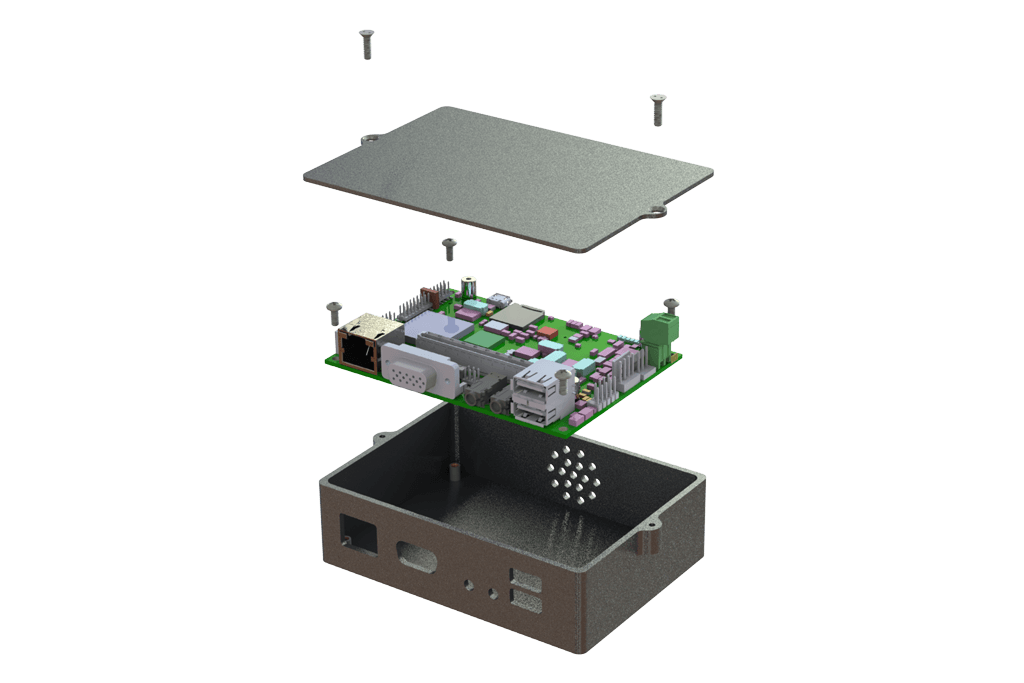

Ibis Networks

IoT device to monitor electrical usage

3D Printing

Custom 3D Printing/Additive Manufacturing

Electronic Housing

Multi material design

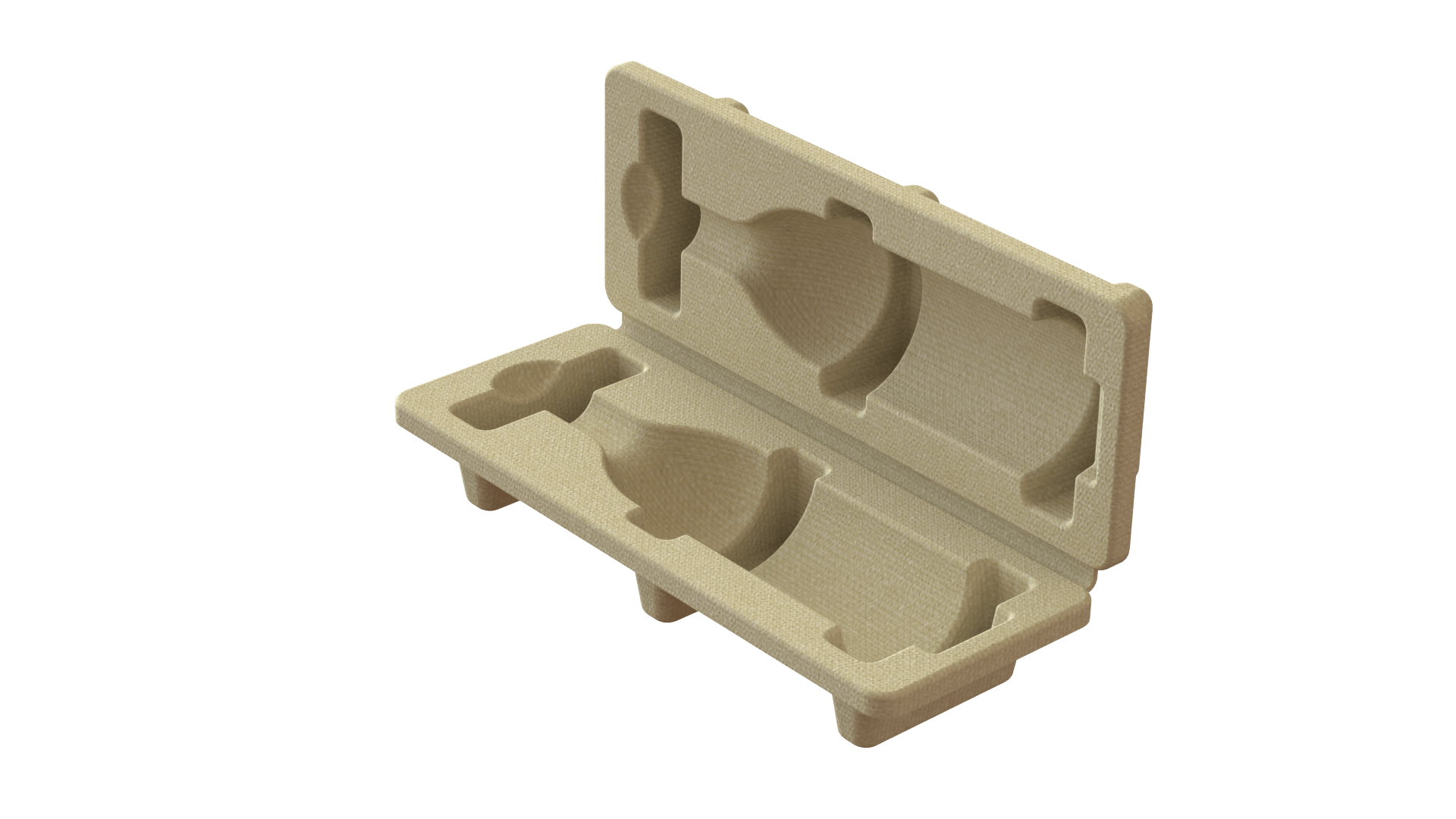

Paper Pulp Packaging

Environmentally friendly Paper Pulp Packaging product

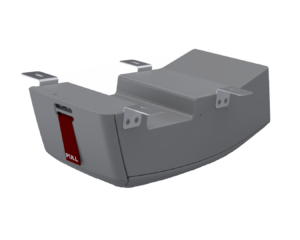

Aerospace

Emergency Vision Assurance System (EVAS®)

Thermoformed tray for food product

Recycled PET material

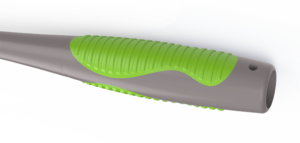

Overmolded Handle

Ergonomic custom handle design with multi materials for handling comfort

Skout Cycling Gear

Ultimate Protection Against Handlebar Impact

The BabyToon

AS SEEN ON SHARK TANK

Silicone baby spoon

Pupu Cooler

Keeps your Pupu’s cold and fresh

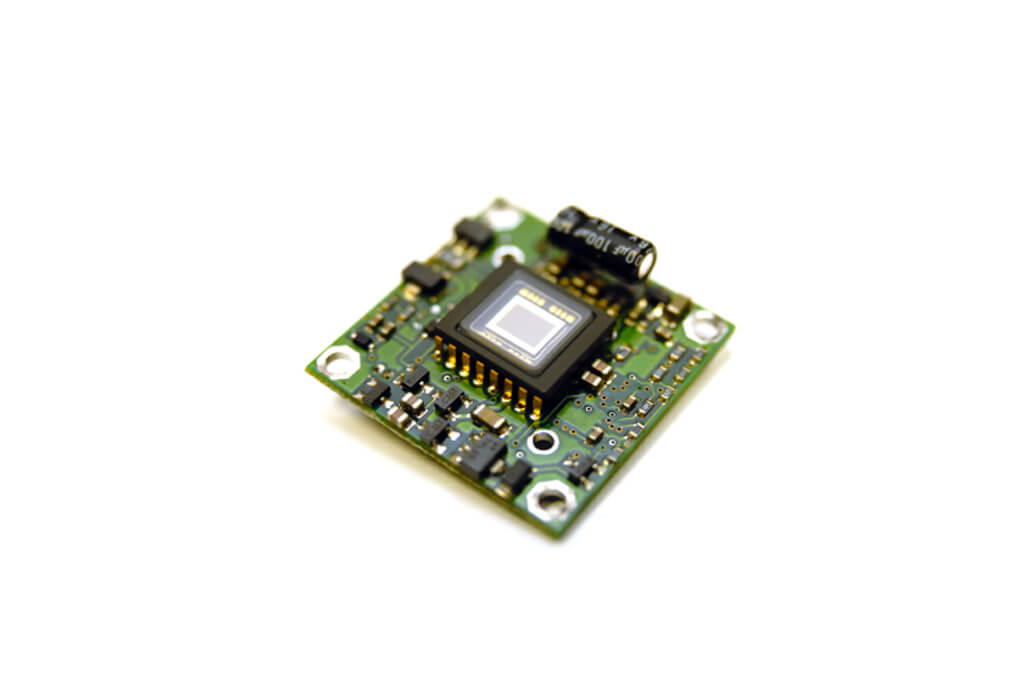

Custom Electronic Device

Proprietary electronic device

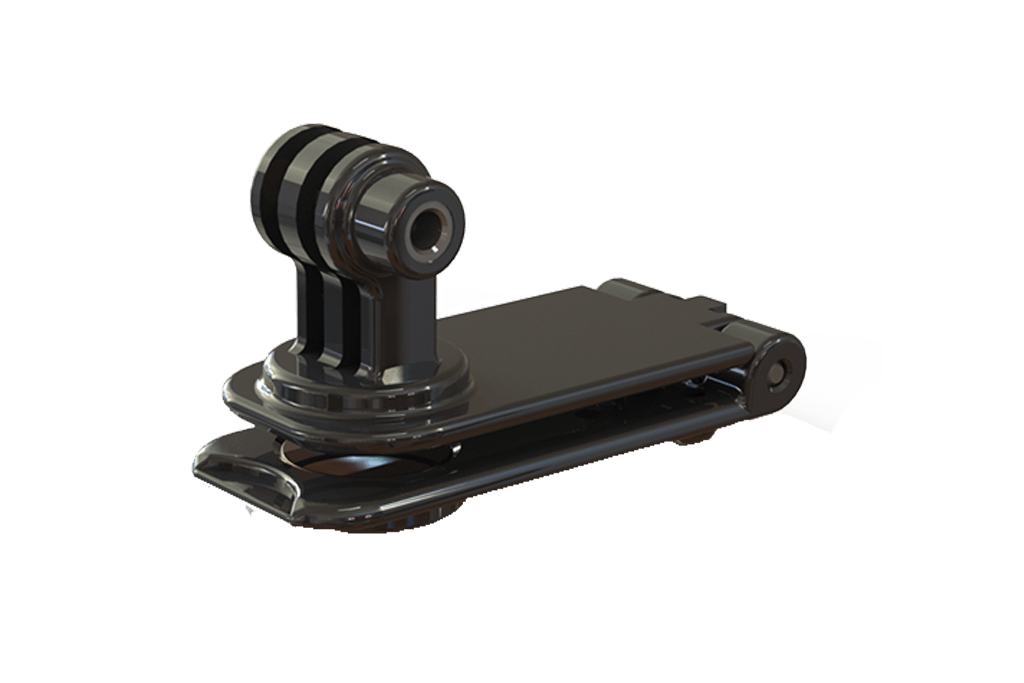

GoPro Hat Clip Mount

Attach your GoPro clip to your hat

Weed Wacker Tool

Line feeder attachment for weed wacker

Electro-Mechanical Design

Power Distribution Unit

DESIGN, PROTOTYPE & MANUFACTURING INDUSTRIES SUPPORTED

Consumer Products

Developing market ready products that range from a wide array of applications.

Scientific

From Astronomy to Underwater Submersible vehicles.

Aerospace

Creating custom products for complex aeronautical applications.

Inventors

Helping Inventors achieve their goals by creating functional and manufacturable designs.

R&D

Developing ideas from theory to proof of concept to generating functional prototypes.

Industrial/Construction

Supporting large industrial and construction applications, contractors and architects are able to build better products.

Medical

Integrating R&D processes to develop new products that aide in medical advancements.

Automotive

Creating products for use in OEM and aftermarket industries.

Military

Supporting DoD programs to create technologically advanced products for commercial and military applications.

Positive Feedback

Parts Designed

Parts Manufactured

Layers 3D Printed

TESTIMONIALS – What others are saying

“3D Innovations has been fantastic. They have basically taken what was a concept in our head to an actual product ready to sell. They really went above and beyond our expectations of improving the design. They recommended little tweaks to our product to make sure its function was at its maximum efficiency. The time and quality of 3D Innovations surpassed our expectations. Their speed and quality is unlike any other we’ve seen before. We would definitely use 3D Innovations again! The amazing part is that the computer drawing is EXACTLY what the prototype turned out to look like. So we are able to save money and time knowing that what we see on the computer is what we will get manufactured. This helped us adjust the product accordingly without having to make multiple prototypes to get exactly what we wanted. This process and technology probably saved us hundreds, if not thousands of dollars.”

Pacific Ocean Dreams,

“We engaged Collin at 3D Innovations to manufacture vintage 60-year-old jalousie window cranks that are no longer made. He took our original broken crank and created a 3D file; then, we paid for a test crank made of less expensive material to ensure a good fit. This fine-tuning helped with the final window cranks before heavy-duty material was used. Collin made a complicated process more accessible, and we would use him again. He went above what was expected, and we appreciated his time!”

Pumehana N.

“Thanks for everything Collin. Couldn’t have done it without you. I look forward to working on future SKOUT projects with you. None of this would have been possible without our initial meetings and all the hard work you and your team put into those hard plastic prototypes and designs. Forever grateful.”

Laurens Miller, Owner & Founder

“Using their 3D design process, I was able to view and verify my design before any prototypes were built, which saved me thousands of dollars in re-work or modifications. I was able to use the design files to generate photorealistic renderings that I used for advertising and marketing. Their experience and knowledge with molding and tooling helped improve my product and gave me a clear understanding on how it was going to be manufactured. 3D Innovations has been a great full service solutions provider in helping me take my product from concept to the manufacturing phase. I personally recommend using 3D Innovations to anyone developing a new invention.”

“3D Innovations was efficient, current with technology during the design and engineering process, and aware of staying within our financial budget. Our family was not only educated and received expert advice through the process, but we gained a friend who we enjoyed working with.”

“I came to Collin Kobayashi at 3D Innovations several years ago with a product invention that I wanted to take to market. I didn’t push through on that idea, however, I recently returned with another project. After submitting some rough sketches and a picture of my cardboard “prototype”, Collin rendered my invention EXACTLY as I envisioned it. An idea that was hatched (in my mind) eight years ago is now finally coming to life with Collin’s skill and expertise. I’m extremely happy with my experience and the deliverables produced by 3D Innovations!”

“We started with an idea that existed only as simple drawings and general concepts. After contracting 3D Innovations LLC to help us take our product design to the next level, the results have surpassed everyone’s expectations. Building a virtual model has allowed us to catch design problems well before the actual fabrication. That has saved us a ton of time and money!”

“I feel very lucky to have found 3-D Innovations, LLC to take on my project. My drawings were rough, lacking detail and inaccurate, but Collin worked with me and the drawings and prototype surpassed my greatest expectations. I have and will continue to recommend 3-D Innovations to my friends or anyone that might need this service. Service is what they are all about. Great job.”

Wayne Bailey

Ready to discuss?

Tell us what you’re interested in and we will get back to you.