The initial idea for The BabyToon came from a science project Cassidy did in the 3rd grade. After thinking about the problem that she was trying to solve, she decided to take this concept and further develop it into a commercial product. After mass producing The BabyToon, Cassidy was featured on Season 11 of Shark Tank and received a deal with Lori Greiner and eventually licensed her product to Munchkin.

The BabyToon Showcase video

The BabyToon was featured on Season 11 of Shark Tank. Watch to see if Cassidy was able to close a deal with any of the sharks!

Developing a custom solution for existing installations of electronic door locks in a major hotel chain.

Developed during the COVID-19 pandemic, the IllumeRx Goggle is an integrative eyewear platform for sealed goggle with filter and accessory options that create a new standard of protection for infectious diseases.

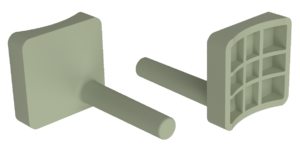

Designing aftermarket or obsolete OEM parts can have particular advantages and suit various applications.

The ultimate automotive wheel detailing brush is here. Use Brush Knuckles on your car, truck, ATV, motorcycle, and other hard to clean areas.

Reproduction of obsolete parts is becoming a common practice with the advancement of 3D Printing and Prototyping methods.

These parts were no longer being manufactured by the OEM company so replacement parts were obsolete and impossible to obtain. The existing parts were used to reverse engineer a design that could replicate the function while maintaining the structural integrity, thermal property requirements, and cost.

A minimally invasive method to collect biological tissue samples from specific marine species. This biopsy dart can be mounted on a tethered pole, harpoon, lance, spear, arrow, or other striking device using a standard M8 thread.

The device is capable of collecting 1.5cm3 of tissue sample.

The Sand Anchor was developed to keep pop up tents, umbrellas, and canopy tents from flying away while at the beach.

An innovative way of using recycled and sustainable materials to produce product packaging while keeping our environment free of plastic waste.

Developed for a team of young entrepreneurs, this GoPro accessory can replace over a dozen mounts for your GoPro, iPhone, audio recorder & lights with a simple to use, compact and hands-free mount. Learn how it was first developed in less than 54 hours!

Electronic devices for the Medical and Consumer markets require additional steps for commercialization. Learn how this product was developed for a customized application and finalized for pre-production manufacturing.

Going from Design to Manufacturing, 3D Printed prototypes were created to assist with developing a manufacturable design that was used for pre-sales, marketing, and content creation. See how prototyping and tooling costs were reduced.

Learn how product licensing can be a better alternative to manufacturing. Inventors have several options when bringing new products to market.

See how a new product was developed to help fight against children’s cavities and a fun new way of brushing.