Can Additive Manufacturing be used to create end use parts?

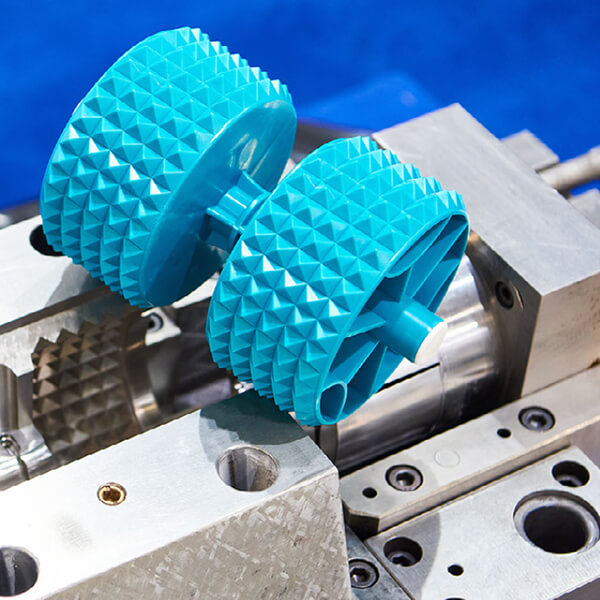

There is often a misconception about 3D Printed parts being used solely for prototyping. In recent years Additive Manufacturing or 3D Printing has evolved in the types of materials available…