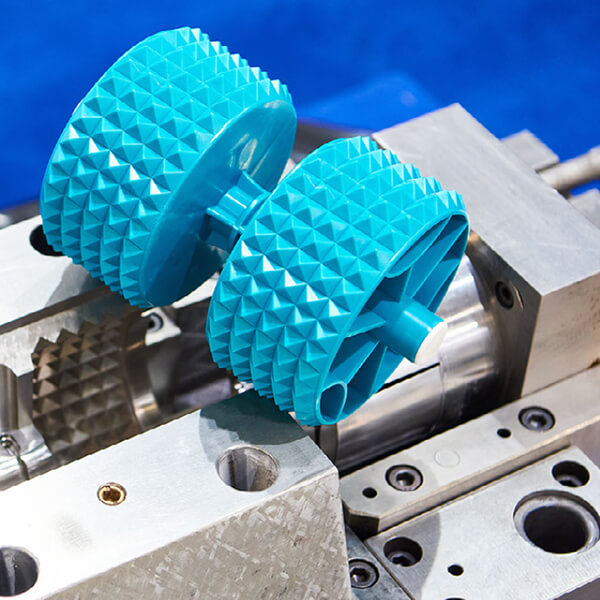

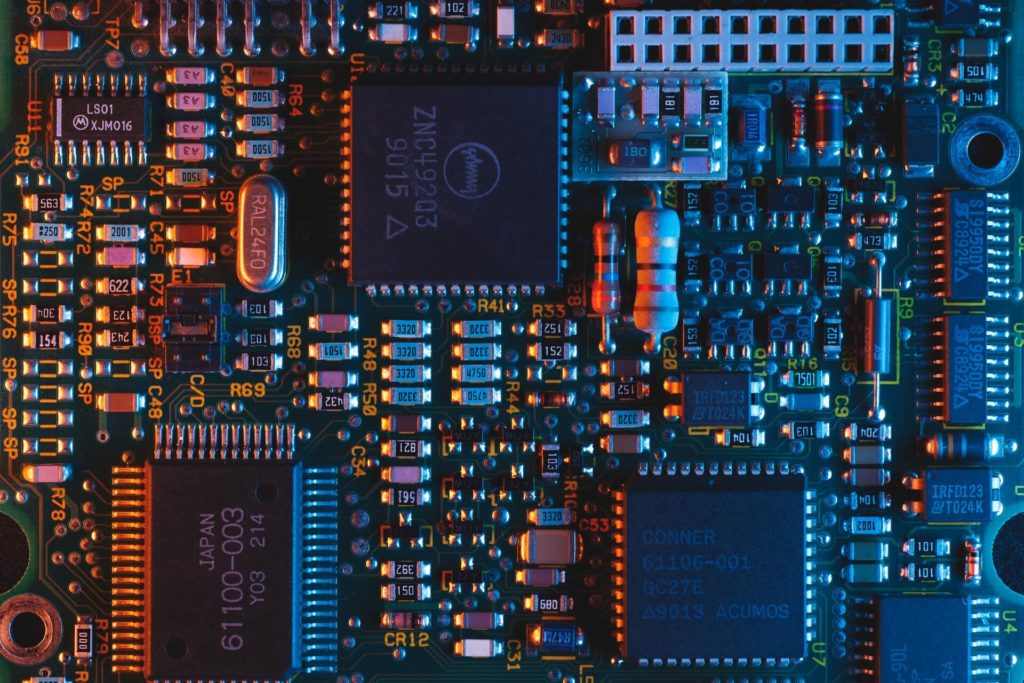

How To Transition From Prototype To Mass Production Manufacturing

Transitioning from a prototype to production manufacturing involves a series of steps to ensure a smooth and successful transition. Below is a general outline of the process used to allow…