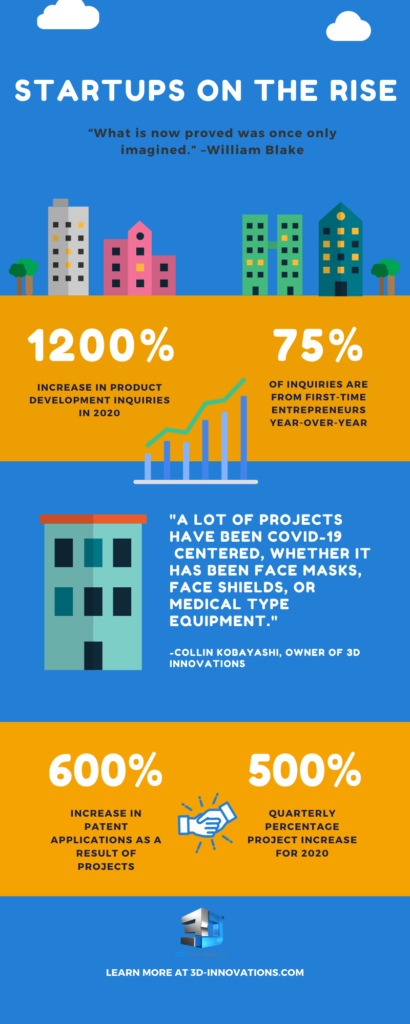

Fast Track Commercialization with a Product Development Partner

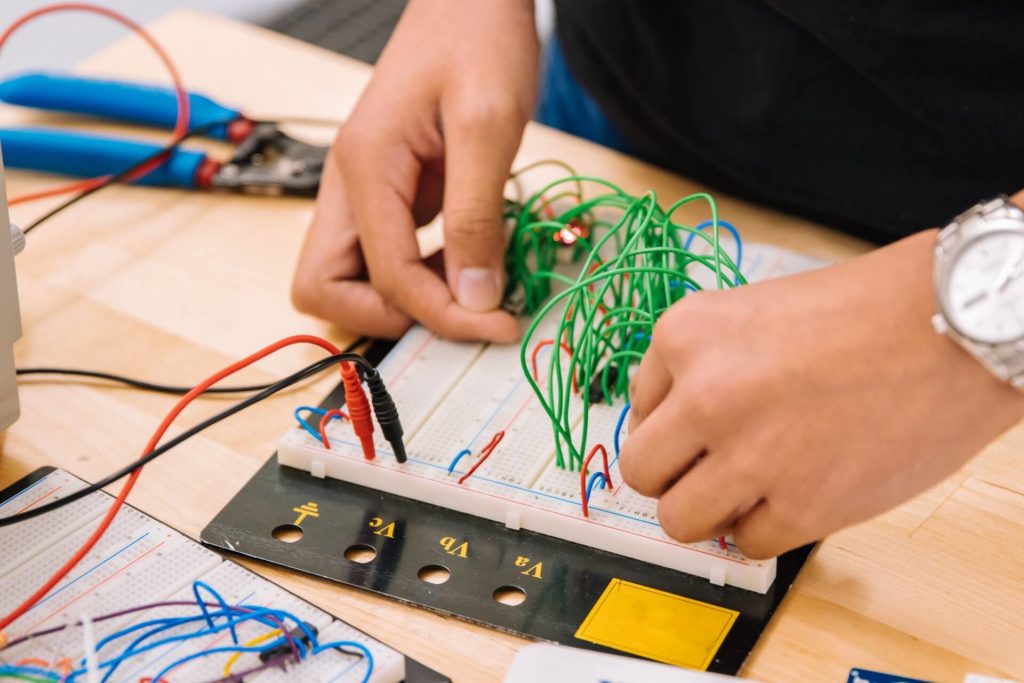

When you start on the journey to developing a product, whether you are a first-time entrepreneur or seasoned business owner, there are always unforeseen challenges that arise along the way.…