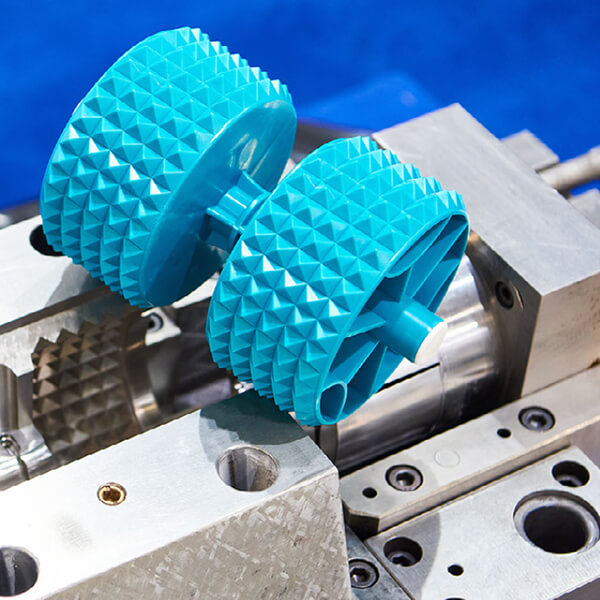

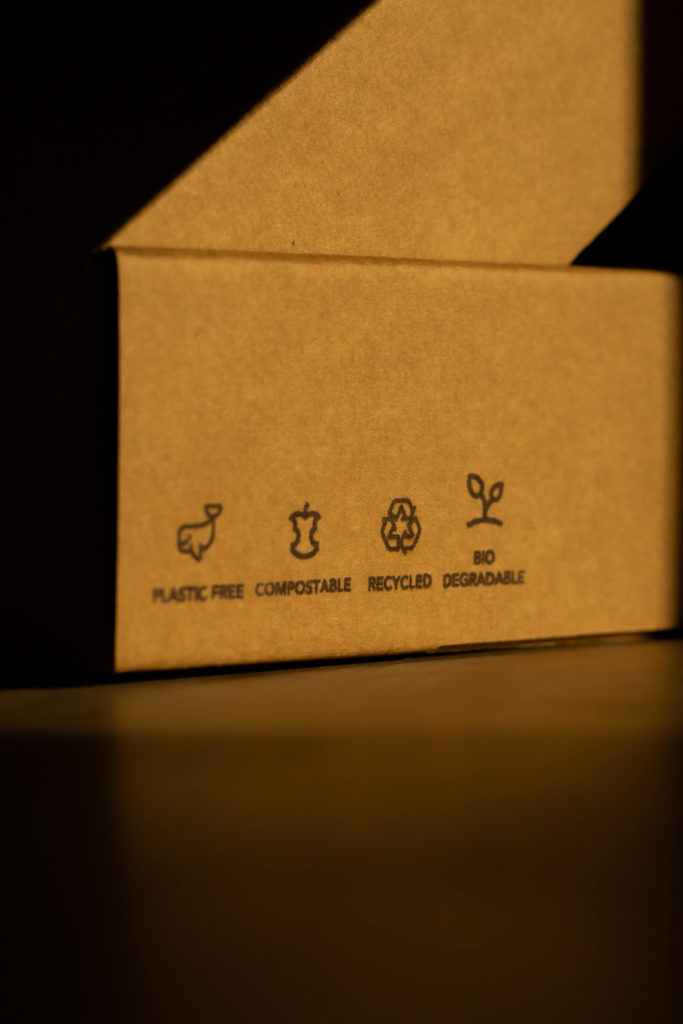

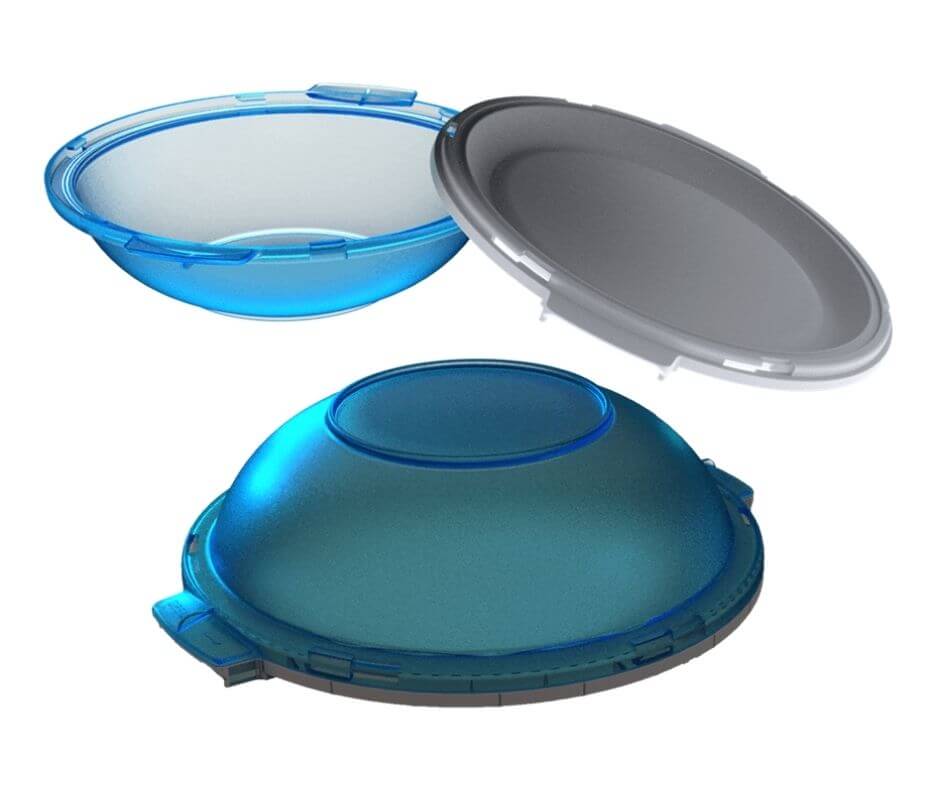

Common Types of recycled material used in Production Manufacturing

Manufacturers use a variety of recycled materials to produce products, promoting sustainability and reducing the environmental impact. Here are some types of recycled materials commonly used in manufacturing. …