Getting started with 3D printing technology is exciting, however, it often comes with a great deal of questions. Below we answer some of the most common questions we receive.

Getting started with 3D printing technology is exciting, however, it often comes with a great deal of questions. Below we answer some of the most common questions we receive.

3D printing is one of those technologies that captures the imagination because of the seemingly endless possibilities of it. The ability to fabricate a product on-demand in mere hours, rather than weeks, is a huge reason why entrepreneurs often turn to the technology.

What is 3D Printing?

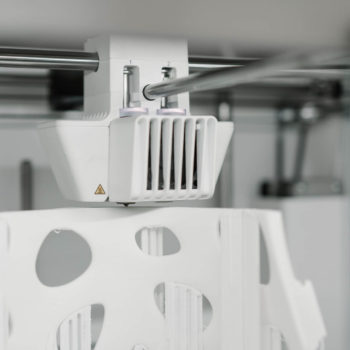

3D printing, or additive manufacturing, is a manufacturing method that builds an object layer by layer, with each layer of material the object is closer to completion.

A digital CAD file feeds the 3D printing machine the information that it needs to create the object. “Depending on the technology, the 3D printer deposits material, selectively melts and fuses powder, or cures liquid photopolymer materials to create parts based on the data delivered to it. The 3D printed parts often require some form of cleaning and finishing to achieve their final properties and appearance before they’re ready to use.” (Formlabs)

Are there different types of 3D Printing?

Yes, there are seven different categories of 3D printing, or additive manufacturing, processes have been identified and established. These seven 3D printing processes brought forth eleven different types of 3D printing technology that 3D printers use today. All3DP has a great guide to the different types available (link here).

Material Extrusion devices are the most commonly available — and the cheapest — types of 3D printing technology in the world. You might be familiar with them as Fused Deposition Modeling, or FDM.

What materials are available for 3D Printing projects?

Currently, the most common materials used for 3D printing projects are plastics and metals. There are a range of other materials that have been developed, but are not as widely used (i.e. ceramics, wood and glass).

How can 3D Printing technology help my startup?

Additive manufacturing is ideal for a range of product development and manufacturing applications—prototyping, tooling, highly customized parts and short-run productions to name a few. 3D manufacturing technology excels when it comes to product design. Complex geometries offer a high degree of design freedom that traditional manufacturing methods just can’t reach.

Another benefit of the technology is that it is often cheaper to use for prototyping than traditional manufacturing methods. Quick turnaround along with decreased costs make it a favorite for entrepreneurs developing a product.

Is 3D Printing a “Push Button” technology?

There is nothing “push button” about 3Dprinting technology. There is a lot of hard work that goes into making a successful print.

The first step in being able to start the 3D Printing process is to have a “water tight” 3D model. This can be done in one of two ways.

- The first method is to use a 3D CAD program or 3D modeling program to create your design. If you don’t have the skillset to do so, working with a product development company can assist you in creating your design.

- The second option, if you are looking for a generic design, often times you can find various file share or open source websites that users have created designs for. These can be purchased or in some cases downloaded for free. While the market has expanded to companies offering “downloadable” files for use, these files are as is and will require experience using 3D modeling programs to make adjustments or modifications to the design. In most cases, what you download is what you get.

Now that you have a little background into the technology and what it can do for you, it’s time to get started.

Related 3D Printing Technology Blog Posts

- Is 3D Printing Right for Your Project?

- Combining 3D Manufacturing & Traditional Manufacturing for Success

- 5 Popular Additive Manufacturing Myths Debunked

Have additional questions about 3D printing? Send us an email at info@3d-innovations.com today.

______

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.