We hear a lot about 3D printing technology, however as we have previously discussed it is not exactly a “push button” technology. 3D printed parts require extensive design considerations before the print and post processing after the object has been created. Below we discuss 3D printing post processing considerations further.

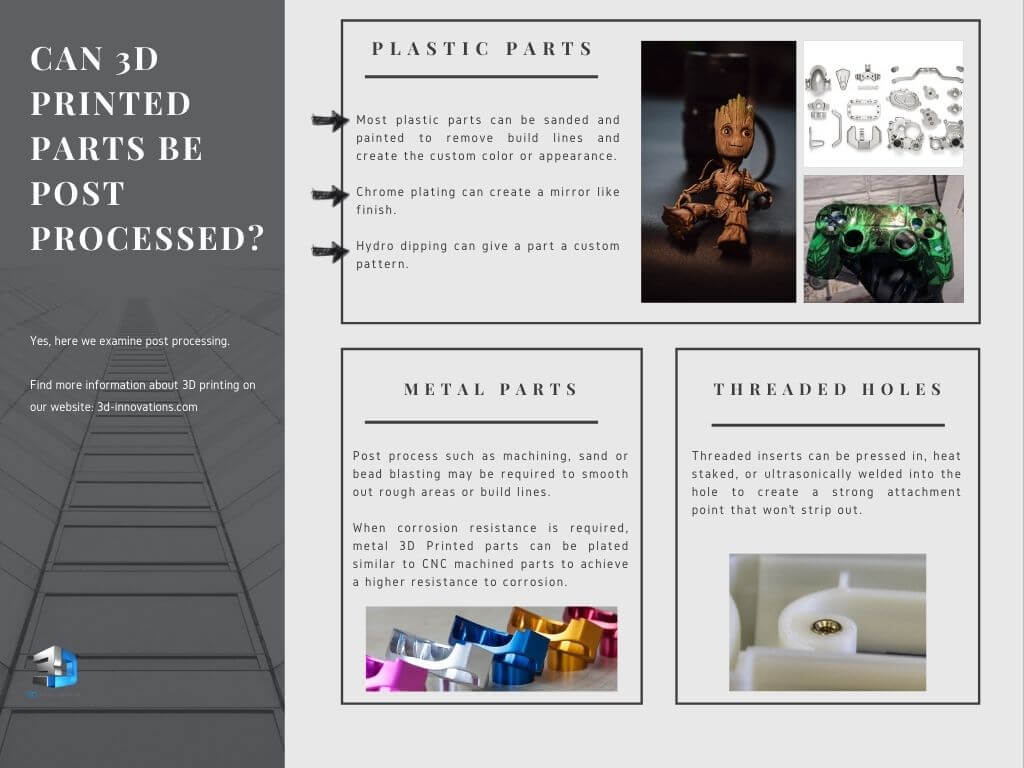

Plastic Parts

- Most plastic parts can be sanded and painted to remove build lines and create the custom color or appearance that you are looking for. Parts built with the FDM (Fused Deposition Modeling) process may require additional time to remove build lines but can produce a smooth part.

- If a more refined look is required, chrome plating can be used to create a mirror like finish.

- Hydro dipping can create a unique look by adding a custom pattern to give your part the appearance of wood, carbon fiber, brushed metal, and many other patterns to add a stylized look. “Hydro dipping (also known as immersion printing, water transfer printing and hydro imaging ) is a unique process that allows you to apply graphics to almost any three-dimensional object. This process has been used for years in the auto industry along with many other fields. Other items like firearms, helmets, gaming controllers & ATV’s are widely decorated with hydro films these days. There are many different materials (substrates) the film can be applied on such as plastic, metal, wood, and more.” (Hydro Creations)

Metal Parts

- If parts built with metal 3D printing result in a finish or texture that is not desired, post process such as machining, sand or bead blasting may be required to smooth out rough areas or build lines.

- When corrosion resistance is required, metal 3D Printed parts can be plated similar to CNC machined parts to achieve a higher resistance to corrosion.

Threaded holes

- Adding tapped or threaded holes to plastic parts will likely yield a weak connection point as the plastic material is soft and threads will not hold up for long periods of time. Self-tapping screws can be used instead of tapping the hole for use with a machine screw. Often, using a threaded insert will allow for constant removal of the screw without affecting the integrity of the part. Threaded inserts can be pressed in, heat staked, or ultrasonically welded into the hole to create a strong attachment point that won’t strip out.

Have additional questions about developing your product? Send us an email at info@3d-innovations.com

_____

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Subscribe to the 3D Innovations newsletter on our Facebook page!