Transitioning from a prototype to production manufacturing involves a series of steps to ensure a smooth and successful transition. Below is a general outline of the process used to allow for a smooth production of your project.

- Conduct a Design for Manufacturing (DFM) Review. Evaluate your prototype design for manufacturability. Identify any design changes or optimizations needed to streamline production, reduce costs, and improve scalability. This can also include Process Optimization to analyze the results of the pilot production run and identify areas for improvement. The process should also look at refining the manufacturing process to increase efficiency, reduce waste, and enhance product quality.

- Define Quality Control and Testing requirements. Establish robust quality control measures to ensure consistency and reliability in the final product. Develop testing protocols to verify the product’s performance and compliance with standards. Using an Engineering Validation Testing (EVT) process to conduct rigorous testing of the prototype under production-like conditions to validate its performance and reliability. Identify any issues and make necessary refinements.

- Design Iterations. Incorporate any changes or improvements identified during EVT into the prototype design. Update the documentation and specifications accordingly..

- Design for Assembly (DFA) Review. Assess the design for ease of assembly. Identify opportunities to simplify the assembly processes, reduce labor time, and minimize potential errors. This could also include documentation and training by creating detailed documentation and work instructions for manufacturing processes, assembly procedures, and quality control standards. Train the production team to ensure consistency and adherence to the established procedures.

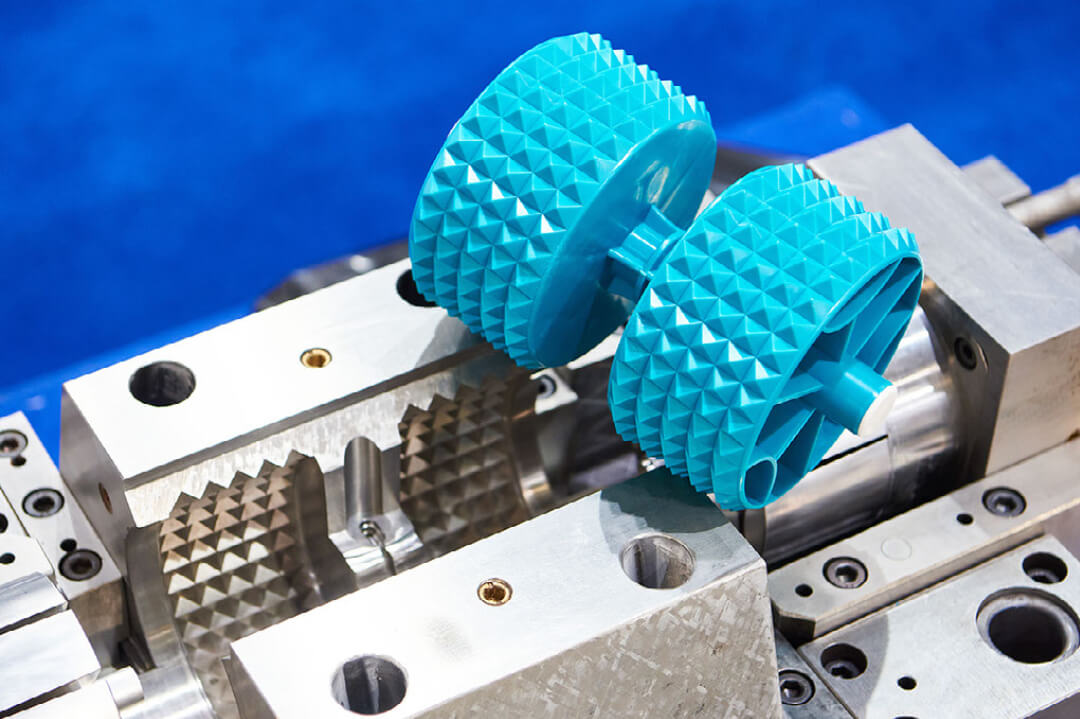

- Supplier Selection. Identify and establish relationships with suppliers who can provide the required components and materials for production at the desired scale. Evaluate their capabilities, reliability, and cost-effectiveness. 3D Innovations has a vast array of manufacturing partners that are able to produce low and high volume quantities using production methods such as Injection Molding, Blow Molding, and other manufacturing capabilities.

It’s important to note that the transition from prototype to production manufacturing can vary significantly depending on the complexity of the product, industry requirements, and other factors. Seeking guidance from experienced professionals and consulting with experts in manufacturing can be beneficial in navigating this process successfully.

Contact us to learn about the specific steps and requirements to ensure that your project goes off without a hitch!

______

Developing Ideas From Concept To Product®

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Connect with us on Twitter, Facebook, Instagram, & LinkedIn today.