CASE STUDY

The Challenge: Develop Functional Prototypes To Mimic A Molded Part

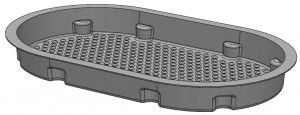

Our customer required Product Development support for a new product that was to be introduced to the market. Similar products were thermoformed to produce the commercial products, but as with any new product being developed, avoiding any type of tooling was going to accelerate the design and prototyping processes.

Thermoforming is a process of taking thin sheets of plastic material, typically High Impact Polystyrene (HIPS), (PET), or Polypropylene (PP) that is heated and formed over a mold. Producing the mold can be costly and would only be done to produce the final parts.

This project required creating a new design and also a prototype. Walls were .018” – .022” thick making the process of 3D Printing the part successfully very challenging due to the wall thickness. Most process can accommodate features greater than .020” thick. The design required the part to maintain this thin wall so that it would function properly. As with any design, the challenge is not only designing to work properly, but being able to functionally test it.

Other prototype development methods were explored to produce these prototypes, but machining this type of part would not only be very costly, but also difficult due to its geometry and thin walls.

Other prototype development methods were explored to produce these prototypes, but machining this type of part would not only be very costly, but also difficult due to its geometry and thin walls.

Using a relatively inexpensive 3D Printing process, we were able to successfully develop functional prototypes that were then used for testing.

In the end, a successful set of prototypes were built and delivered to the customer for review and testing before moving into the production manufacturing stage.

The costs for several sets of prototypes were approximately 600% less versus the cost of using a machining process.

________

3D Innovations is a full service 3D Engineering/Design company – from the 3D Design to a fully functional 3D Prototype & Product.

Subscribe to the 3D Innovations newsletter on our Facebook page!