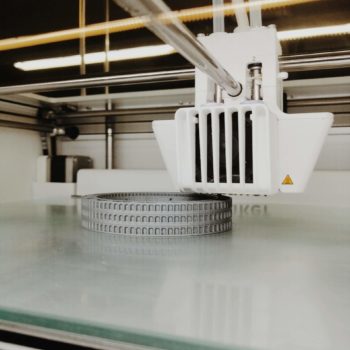

Prototyping is the bread and butter for 3D printing technology.

Prototyping is the bread and butter for 3D printing technology.

For years, 3D printing has been synonymous with the prototyping phase of product development. It has not been until recent years that businesses and manufacturers have turned to the technology for end-use parts. While 3D printing technology has rapidly advanced to include new methodology and materials, it is still widely used for product prototyping. Below are four considerations when it comes to 3D printing a prototype.

Complex Geometries

Design complexity is an area where 3D printing shines. Complex geometries, internal features and built-in interlocking objects with no assembly required are all possible. With these additional design capabilities, 3D printing creates new product design opportunities.

Since 3D printing builds your design layer by layer, your product design can include intricate details both internally and externally along with geometric shapes that were once impossible to manufacture.

Quick Turnaround

Where once prototyping took weeks, 3D printing has now brought this time frame down to mere hours. A quick turnaround for your prototype means that you quickly print and test your idea. You are also able to print different iterations of your product.

Environmentally Friendly

With traditional subtractive manufacturing, your design is cut from a piece of raw material, which means there is a substantial amount of material waste. Since 3D printing is only printing your design, there is not a lot of leftover material.

“Today, the average waste from a traditional manufacturing is 21% of the materials. Not only does 3D printing reduce overall waste of materials to below 10%, but it also reduces carbon emissions substantially.” (Machine Design)

Businesses and governments around the globe are working hard to reduce their carbon footprint and environmental impact, and the use of 3D printing technology is one way of doing just that.

3D Printing Isn’t a “Push Button” Technology

3D printing, in a sense, is a secondary process and a lot of work comes before you start printing. Your design needs to be designed using CAD software. This CAD file (.STL) feeds the 3D printing machine the information that it needs to create the object.

“Not only does a CAD file help save time when figuring out all the finer details of a part by looking at the 3D model, but it also allows a model to be magnified and even rotate on any axis to get a full three-dimensional concept of the part, which allows you a greater sense of the product. Using CAD makes it possible to simulate the movement of a part as well.” (Vista Industrial)

With CAD simulations you can get a real feel for your product and conduct stress testing before you ever have it in your hands. Once you have a design and it has been tested, then it is time to head to the 3D printer. Depending on the size of your product, print times vary, but most take a few hours.

3D printing a prototype is certainly the fastest way to test your product and make the necessary design changes before entering the manufacturing phase of product development.

______

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Subscribe to the 3D Innovations newsletter on our Facebook page!