Less than ten years ago, the hype surround 3D printing technology was at an all-time high. The idea of each household having one led the news cycle. In hindsight, it is clear that this level of hype and the fever-pitch level of excitement was not sustainable or even realistic. There were far too many barriers for the technology to overcome, both technological and usability, before it could be in “everyone’s house”.

Less than ten years ago, the hype surround 3D printing technology was at an all-time high. The idea of each household having one led the news cycle. In hindsight, it is clear that this level of hype and the fever-pitch level of excitement was not sustainable or even realistic. There were far too many barriers for the technology to overcome, both technological and usability, before it could be in “everyone’s house”.

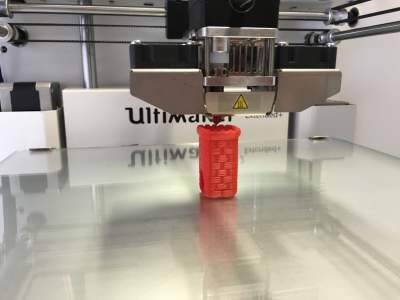

Over time the hype slowly diminished, and the technology began to steadily mature. Firms focused on 3D printing began to collaborate, merge and narrow their focus. Today, the future of the technology looks considerably different than it once did. Below are three areas of growth for 3D printing technology and a sign of where the technology is heading.

Industrial 3D Printing

3D printing is making its way onto the manufacturing floor. A recent survey from Jabil, found that “81% of manufacturers are using 3D printing technology today”. It seems that additive manufacturing has found its niche in mainstream manufacturing.

The fact that 3D printing has become so prominent with manufacturers, shows that companies are looking for ways to incorporate this technology into their product designs. Companies are no longer standing on the sidelines waiting to see how the technology matures, but are instead harnessing its design benefits and finding ways to use it themselves.

Material Selection

Where once the only material available was plastic, today there is an ever-increasing range of materials to choose from. The most prominent is still plastic (PLA, ABS, PET, PVA, Nylon) however, metals (steel, gold, silver, titanium), ceramic, and wood options are also quickly coming to market.

New and improved metal 3D printing will make a splash this year. “Metal 3D printing will become more and more of a necessity when solving specific manufacturing challenges and creating customized, complex end-use products.” (Engineering.com) We expect to see the range of materials available to continue to grow as the technology continues to advance.

End-Use Production Parts

Companies, such as GE, are making great strides in advancing 3D printing and its ability to produce end-use products. However, before 3D printing can really take off in terms of end-use production, there are some major barriers that need to be addressed. “Material properties, high costs, complexity, time to a usable part and location of a production-capable machine relegated to an additive manufacturing lab are significant barriers to the use of additive manufacturing in production.” (3D Printing Industry)

Products produced for consumers with 3D printing will be required to meet the same material properties (strength, surface finish, color) that traditional manufacturing has mastered. While it is most likely that end-use production won’t come to fruition in 2018, we can expect to see more companies finding ways of making this happen with one-off parts.

It is clear that additive manufacturing is here to stay. As it is now, this technology continues to excel with its prototyping capabilities and is a great compliment to traditional manufacturing.

_______

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Subscribe to the 3D Innovations newsletter on our Facebook page!