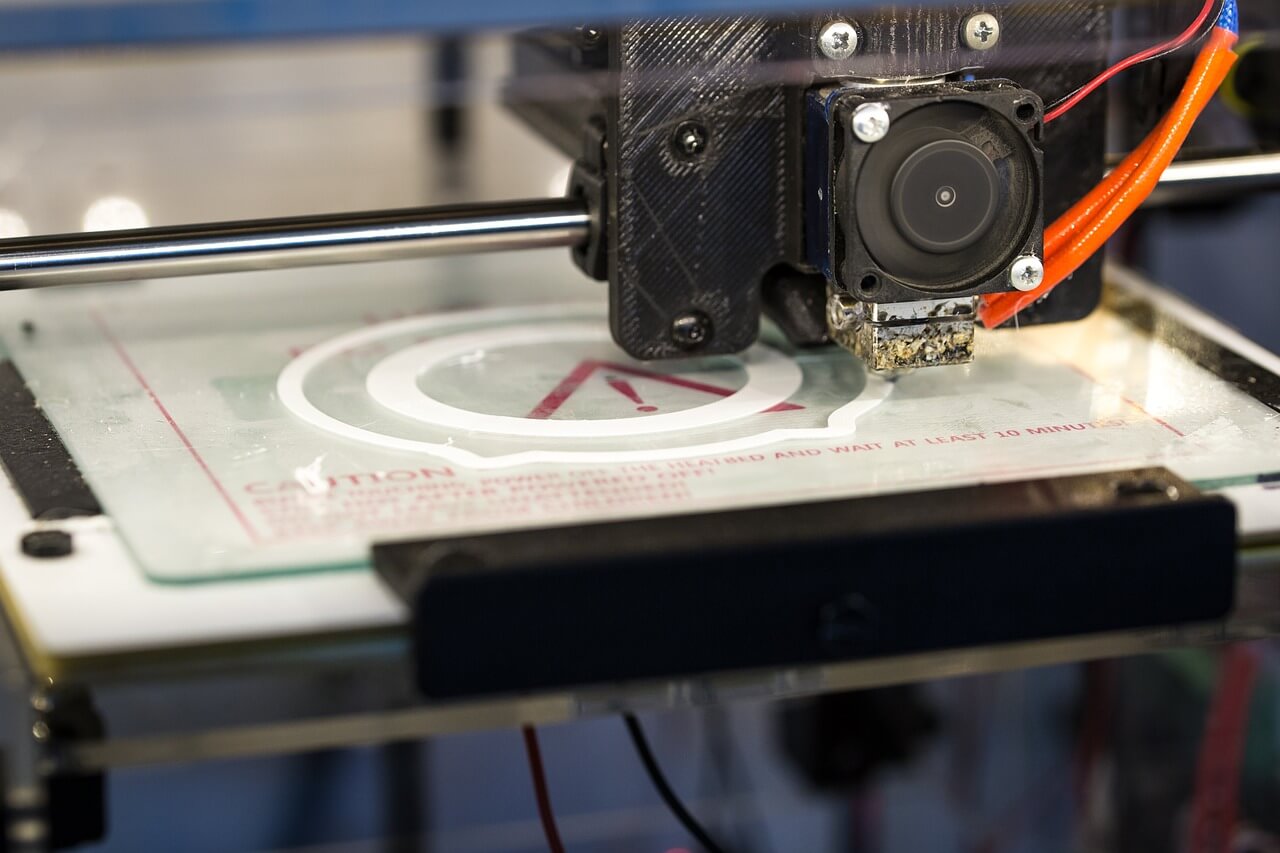

2018 was an excellent year for 3D printing technology and there is no slow down in sight. Below are three major trends to watch for in the additive manufacturing segment in the coming year.

2018 was an excellent year for 3D printing technology and there is no slow down in sight. Below are three major trends to watch for in the additive manufacturing segment in the coming year.

Higher Quality Metal 3D Printing

Metals were a new frontier for 3D printing this year. Businesses wanted to expand beyond the traditional materials associated with 3D printing and into something more durable. Where 3D printing metal parts were once costly to produce, new software and updated technology saw a decrease in price and a rise in quality.

“Metal printing is ideal for smaller scale production projects as it lends itself to production flexibility but at the same time is perfect for designs with high complexity.

Metal additive manufacturing (AM) is on the rise, as the material is ideal for producing lighter items at higher production rates. A recent trend has been to utilize it for seats on aeroplanes. Upon completion, they weighed in an astonishing 50% lighter than their regular counterparts at only 766 grams. As the technology moves forward, we can expect forms of metal printing to change the dynamic of industries.” (Tech Magz)

We will no doubt be hearing about end-use production and more affordable 3D metal printing in 2019 and beyond.

Increased Productivity

Production speed has been a barrier to 3D printing adoption on a mass scale. However, there has been a push by both researchers and 3D printing corporations to increase production speeds, which will help lower this barrier.

“The University of Michigan created an algorithm that reduces vibrations (a significant reason for the reduction of quality of the finished product). Allowing manufacturing speeds to double while producing the same standard of quality, and most importantly to the manufacturers, with no additional hardware costs involved.

In conjunction, MIT engineers developed a desktop printer that has an output times 10 of anything on the commercial market. Using Polymer, fed through the nozzle with a new form of mechanism, it flows faster, and so what would take hours now takes minutes.” (Gadget Miner)

A Rise in Customization

Customization is the “sweet spot” for 3D printing. Major companies and manufacturers have started to take notice that consumers are interested in more customized product options which 3D printing can deliver. The automobile, aerospace and dental industries have been utilizing 3D printings customization ability for years now, but other industries are also starting to take notice.

“Last year Scultpteo’s annual State of 3D printing study showed that offering customized products’ was a top priority for companies who took the survey.

We have seen evidence of this in 2018 with the likes of Adidas, New Balance and Nike already aligning themselves with both household names in the tech and athletics world to experiment with 3D printing to customize their footwear brands that will be designed to the person’s specific biomechanical data.” (Gadget Miner)

As the software advances, materials expand, demand for customization increases and 3D printing production becomes faster, we will see more adoption of the technology across industries. As always, we look forward to the year ahead and can’t wait to see what advancements await.

______

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Subscribe to the 3D Innovations newsletter on our Facebook page!