Using support material is necessary for certain 3D printing processes, such as FDM (Fused Deposition Modeling) or SLA (Stereolithography) printing, where the printer builds the model layer by layer. Support material is typically used to create overhanging or protruding features that would otherwise collapse during the printing process.

Here are some benefits of using support material in 3D printing:

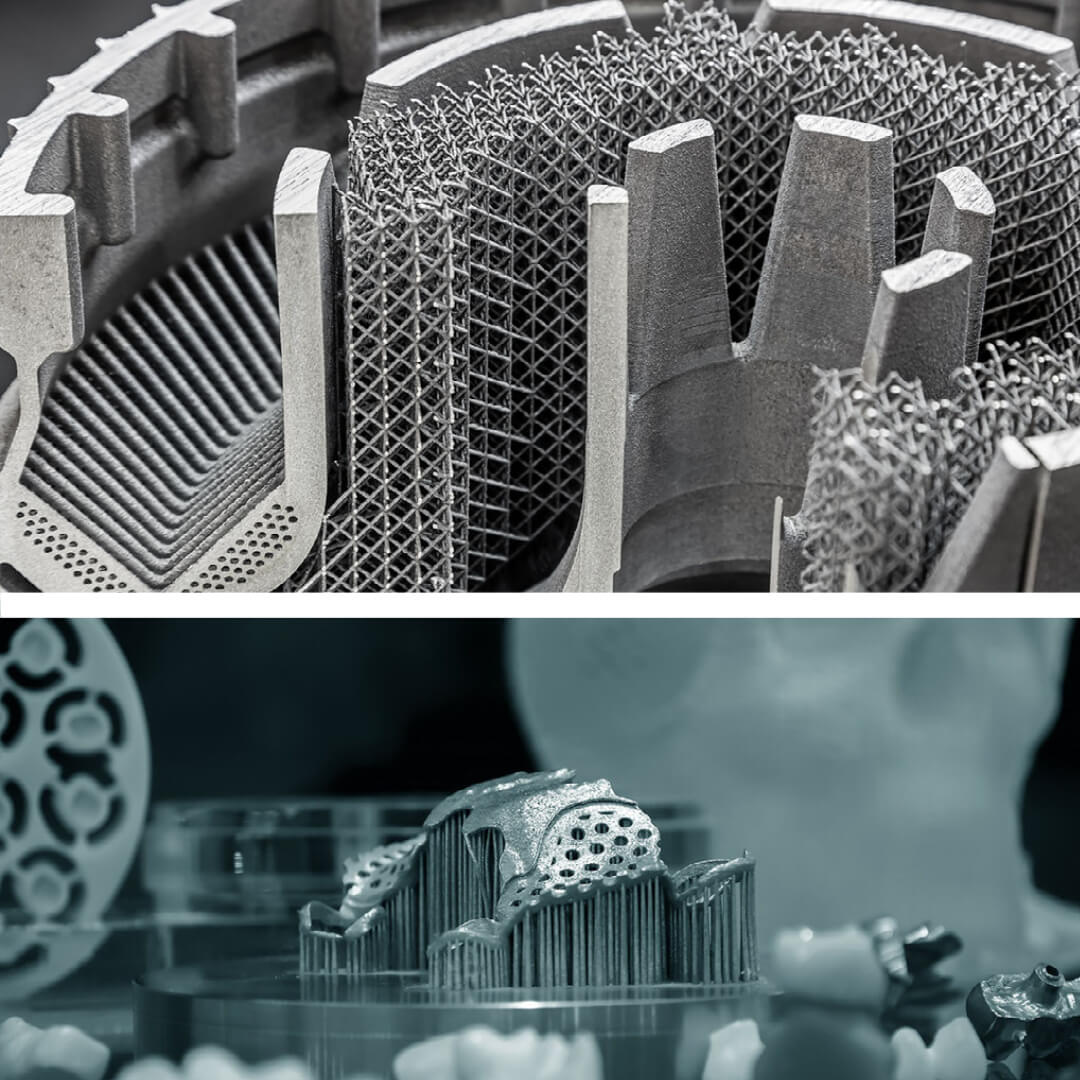

- Enables printing of complex designs: Support material allows for the creation of intricate and complex designs that would otherwise be impossible to print. It can be used to create objects with overhangs, bridges, and other intricate features.

- Improves print quality: Support material helps to prevent sagging or warping of the printed object by providing a temporary support structure for the printed model. This results in better print quality and accuracy.

- Saves material: By using support material only where it is needed, less material is wasted during the printing process. This is particularly important when using expensive or specialty materials.

- Simplifies post-processing: When using support material, the support structures can be easily removed after printing, leaving a clean surface finish. Support material can either be removed chemically or manually. This simplifies post-processing and reduces the amount of time and effort required to finish the printed object.

- More complex geometries could benefit by having support structures in place to ensure the design is built correctly.

- Support material may add cost and lead to a longer build time.

Overall, using support material in 3D printing can help to create more complex designs with better quality, while also reducing material waste and simplifying post-processing.