In the world of technology and engineering, there are a plethora of acronyms referenced. ECAD which stands for Electronic Computer-Aided Design is one you need to know when it comes to creating electronic structures during product development.

In the world of technology and engineering, there are a plethora of acronyms referenced. ECAD which stands for Electronic Computer-Aided Design is one you need to know when it comes to creating electronic structures during product development.

The Definition of ECAD

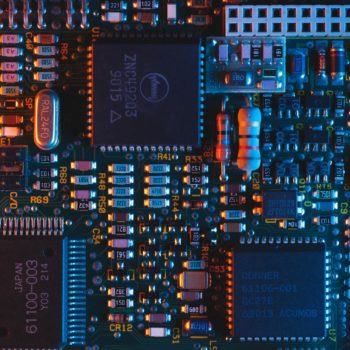

“Electronic Computer-Aided Design (ECAD) – the creation and/or analysis of electronic components, integrated circuits (ICs), modules, printed circuit boards (PCBs), PCB assemblies (PCBAs), and/or electronic systems using computer software.” (Ultra Librarian)

Simply put, ECAD software allows you to efficiently create electronic structures. This is advantageous in today’s product development world because circuit boards are getting smaller and more complex.

Integrating Mechanical Computer-Aided Design with Electronic Computer-Aided Design

Mechanical Computer-Aided Design (MCAD) software allows the designer to create physical structures such as mechanical parts, device enclosures, and mounting components. The software can generate a virtual representation of the pieces as a 3D image and render 2D manufacturing documentation. (Altium)

ECAD and MCAD designers had been used to working in their own silos. Integration and unification were not something that happened early-on in the design phase, in most cases, and often that was because the software available didn’t easily combine these two disciplines. However, as technology has continued to advance, software has made leaps and bounds, and today, ECAD and MCAD are becoming more unified.

Collaborative design with ECAD/MCAD allows the designer to assemble the electrical and mechanical parts in a virtual environment and see if they fit together before being manufactured. The beauty of integrated ECAD/MCAD approach is that errors can be spotted, designs adjusted, and the results validated in minutes.

The Future of Product Development

“As product development changes, electronics design needs to follow. We need to start seeing our PCB designs from a broader perspective, in a 3D world, as part of a complete product development workflow.” (Industry Week)

In today’s product development world collaboration is necessary. Component availability changes, board layouts need to be updated to fit last minutes enclosure adjustments and as smart devices continue to advance, the challenges will become greater. Engineering continues to blend disciplines and having a product development expert that can bring this knowledge to your design is imperative.

This post is part one is a two part series. Our next post will dive into integrating firmware with electrical hardware components and systems.

_____

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Subscribe to the 3D Innovations newsletter on our Facebook page!