It’s no secret that additive manufacturing, commonly referred to as 3D printing, is transforming the business landscape. Within the last decade we have witnessed this technology grow into what it is today, a way to disrupt supply chains and completely innovate the manufacturing landscape—from prototyping to production.

It’s no secret that additive manufacturing, commonly referred to as 3D printing, is transforming the business landscape. Within the last decade we have witnessed this technology grow into what it is today, a way to disrupt supply chains and completely innovate the manufacturing landscape—from prototyping to production.

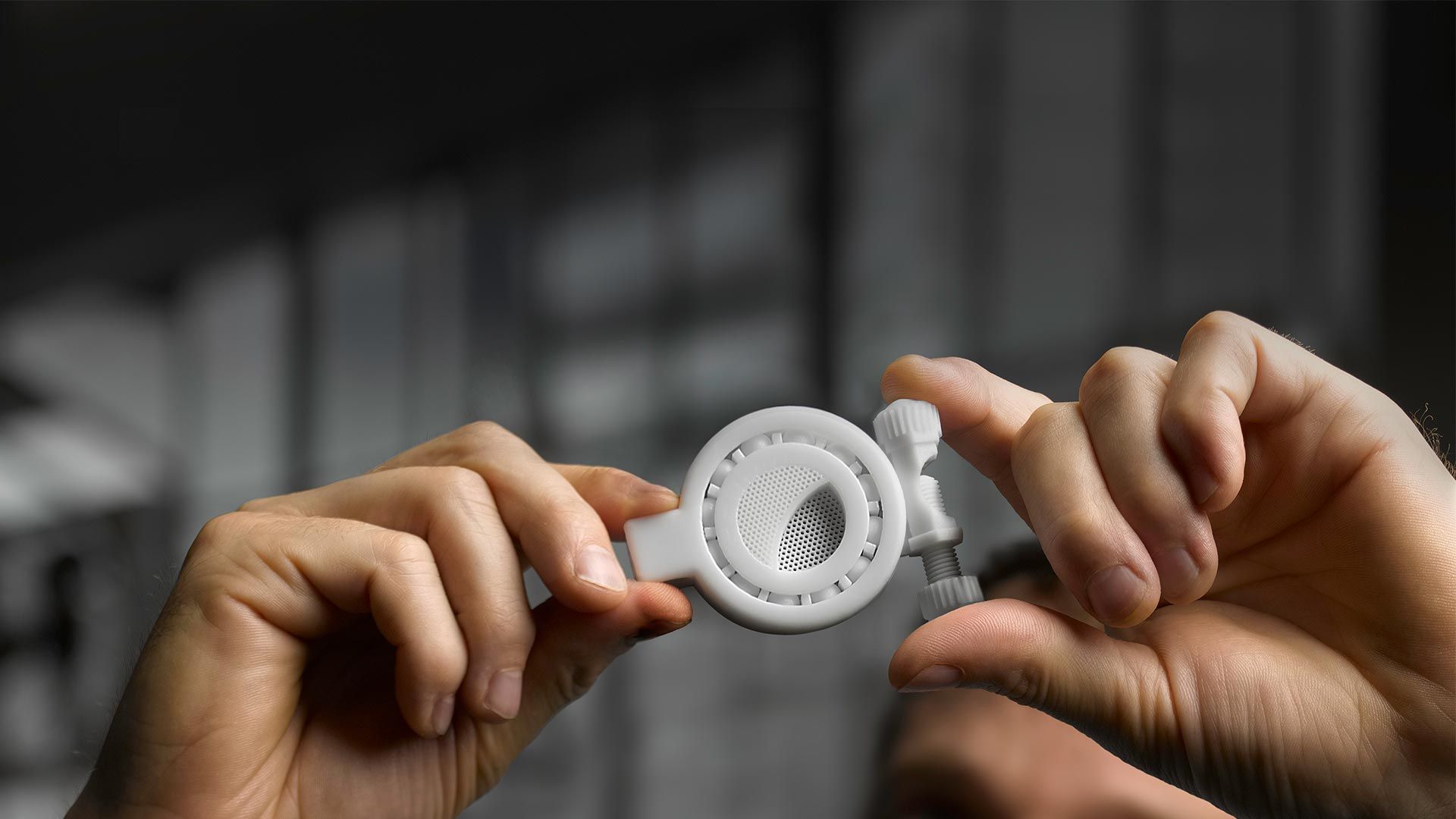

3D printing has been a favorite tool of makers and product design professionals alike because of its quick turnaround time and the fact that it is relatively cheap compared to all other manufacturing methods. 3D printing technology allows designers to quickly, easily and efficiently design and produce a product prototype for review within hours, instead of weeks. While prototyping is where additive manufacturing is most popular and widely used, the technology is beginning to mature and find its way into manufacturing for end-use parts as well.

3D Printing for Prototyping

Our design team regularly uses additive manufacturing technology during the product development cycle when we are working with entrepreneurs and startups on prototyping and finalizing a product design. 3D printing technology is still growing and maturing, it seems that every week new filaments are being developed and new uses for the technology are being discussed. However, as the technology stands today, its strength, its competitive advantage and its usefulness remain in the realm of prototyping. Visual and functional prototyping are imperative when designing a product and this is where 3D printing excels.

3D Printing for Manufacturing

When it comes to manufacturing, 3D printing technology has an advantage on short-runs, however, at this time, it is not able to compete with other traditional forms on a mass-manufacturing scale.

Due to the speed, quality and cost of additive manufacturing, “the technology is best suited for the production of specialty parts in smaller batches, rather than mass-manufactured goods. However, there is an industry shift towards expanding 3D printing technology to take a more prominent role in mass manufacturing. This technology brings some important qualities to the world of manufacturing that make it ideal for certain jobs. For instance, parts can have complex geometries impossible with traditional manufacturing processes. It is also possible to 3D print goods on demand, allowing for easy creation of custom parts” (Engineering.com).

The 3D printing metal segment is making great strides towards high volume manufacturing and McKinsey forecasts the industry to be worth as much as $10 billion by 2030 to 2035. Read more about developments in the metal 3D printing segment on our blog.

3D Printing Quote

At 3D Innovations, we offer 3D printing services to a range of startups, businesses and makers. If you have a design ready to be printed, and would like a quote, please visit our 3D Printing Quote Request page. We have made the quote process quick and easy. Whether you need a prototype or a short manufacturing run, we can help.

______

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Subscribe to the 3D Innovations newsletter on our Facebook page!