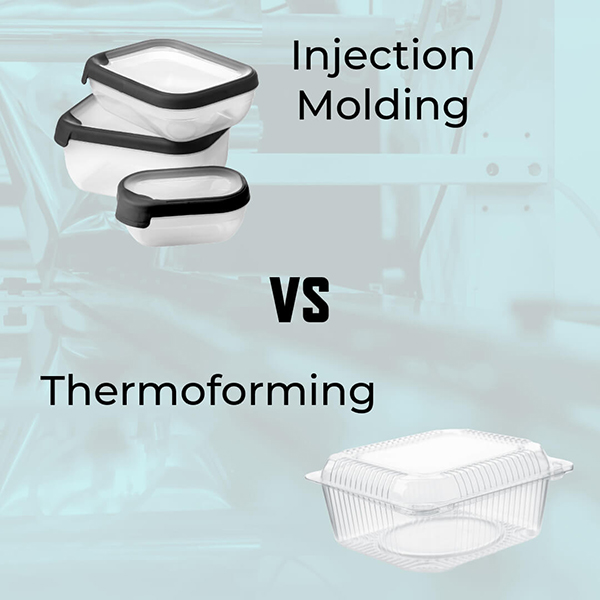

Injection molding and thermoforming are both manufacturing processes used to create plastic parts, but they differ in their methods and applications. Here are the key differences between injection molding and thermoforming.

Process:

Injection Molding: Involves injecting molten plastic material into a mold under high pressure. The plastic cools and solidifies within the mold, taking the shape of the mold cavity.

Thermoforming: Utilizes heat to soften a plastic sheet, which is then stretched or pressed against a mold to form the desired shape. The formed plastic cools and solidifies.

Mold Complexity:

Injection Molding: Well-suited for complex and intricate part geometries. The molds are typically more expensive to create but can be used for high-volume production.

Thermoforming: Better suited for simpler, shallow, and less complex shapes. Molds are less expensive compared to injection molding.

Tooling and Setup:

Injection Molding: Requires intricate and precision-made molds. Tooling setup can take longer and is more expensive.

Thermoforming: Tooling is simpler and quicker to set up. This process is more cost-effective for small to medium production runs.

Production Speed:

Injection Molding: Generally faster in terms of cycle time. It is ideal for high-volume production.

Thermoforming: Slower cycle times compared to injection molding, making it better suited for lower to medium production volumes.

Material Selection:

Injection Molding: Can use a wide range of plastic materials, including high-performance engineering plastics.

Thermoforming: Limited to materials that can be heated and formed easily, typically thermoplastics with lower melting points.

Part Size:

Injection Molding: Suitable for small to large parts, especially with intricate details.

Thermoforming: Often used for larger, shallower parts due to the stretching of the plastic sheet.

Waste Generation:

Injection Molding typically generates less material waste as the excess material is often recycled while Thermoforming may produce more waste, especially in the trimming process/die cutting process.

In summary, injection molding is ideal for complex, high-precision parts with high production volumes, while thermoforming is more suitable for simpler shapes and smaller to medium production volumes with a cost-effective setup. The choice between the two processes depends on the specific requirements of the project.

Contact us to learn more about what process is best for your project.

______

Developing Ideas From Concept To Product®

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Connect with us on Twitter, Facebook, Instagram, & LinkedIn today.