NAME: Collin Kobayashi

EDUCATION: Master’s of Business Administration (MBA), B.S. in Manufacturing Design

3D designers like Collin Kobayashi are engineering the future through innovative product development using 3D technology.

What is your job?

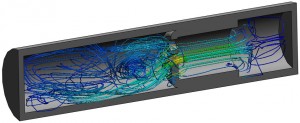

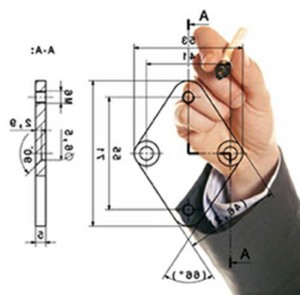

In addition to managing and operating 3D Innovations as President and Principle Consultant, I work to turn 2D sketches into a 3D object through the use of a software program called CAD. CAD stands for Computer-aided Design and is the first step in starting the product development cycle. Most products that are made today are designed through the use of CAD, from your iPhone or iPad to tables and chairs.

I also work in an educational capacity to provide 3D CAD and pre-engineering training for middle, high school, and post- secondary education students with the 3D Academy, a division of 3D Innovations.

Why did you choose this career?

CAD came out in the late 1980’s as a 2D system. My interest in product design started as I was finishing high school in the mid 1990’s. At that time the market was changing from 2D to 3D and once I learned what 3D is all about I was hooked. From there I wanted to be involved with the design and manufacturing processes to learn about different industries and how systems are designed to fit with today’s technology. I was also interested to see the various engineering aspects of technology products.

I was finishing high school in the mid 1990’s. At that time the market was changing from 2D to 3D and once I learned what 3D is all about I was hooked. From there I wanted to be involved with the design and manufacturing processes to learn about different industries and how systems are designed to fit with today’s technology. I was also interested to see the various engineering aspects of technology products.

Once I was established in the field I became interested in helping students learn about 3D engineering. 3D Academy was started as an extension of 3D Innovations, taking the engineering/design and manufacturing processes and integrating it with Science, Technology, Engineering, and Math (STEM) programs that enable students to learn important core academic skills. STEM education has been supported for many years now to provide students with industry and real life skills. My motivation for starting 3D Academy was to provide students with these valuable opportunities that were not available to me during my high school education and to prepare them for a competitive technological career.

Explain what an average day at work is like for you.

When we begin a project for a client, one of the most common things that we get from them is some sort of idea or input that could be in the form of a picture, sketch or in some cases a detailed drawing. Customers come to us because they need to have their idea taken from their 2D format and turned into a 3D model. Once we get the idea plugged into the CAD program we then refine it based on customer needs. Sometimes the clients need the object to look a certain way or function in a certain way and we ensure those aspects are integrated into the 3D model.

Can you talk a little bit about 3D printing?

One of the methods we use to validate a completed design is 3D printing. 3D printing has been around for 15 or so years now, but it has really come alive in the past 2 or 3 years through more robust technology. 3D printing builds a product in layers based on a CAD design. If you can imagine taking an everyday water bottle that stands about 8 inches high, through 3D printing technology we are able to print it in many paper-thin layers and evaluate if our design will work. One of the greatest benefits of 3D printing is that it allows us to test and evaluate product designs before they go to market.

Was there a moment when you knew that you wanted to become a 3D engineer?

Being involved with the advances in the early stages of this industry was exciting and motivated me to continue down this pathway. Being able to see that designing a product or system was within my realm solidified my decision to further develop my knowledge to enter this industry and career path.

Being involved with the advances in the early stages of this industry was exciting and motivated me to continue down this pathway. Being able to see that designing a product or system was within my realm solidified my decision to further develop my knowledge to enter this industry and career path.

What was the biggest challenge you faced in your journey to becoming a 3D engineer?

Most of the technical classes that I took in college were challenging because I was never exposed to the areas that my peers had been exposed to for several years. My personal challenge was trying to keep pace with my peers and apply what I was learning to my educational projects, and eventually my daily career activities. Behind all technical activities lies the entrepreneurial aspect of my business. The main challenges are trying to position the business to provide the best possible service while monitoring any changes in the market that might affect our company business model. Keeping up with technology is always challenging as it changes rapidly and systems quickly become obsolete.

Was there a person who inspired or convinced you to get involved in your field? Who was he/she and how did he/she do it?

Initially, I was not inspired or convinced by anyone to get into the areas of entrepreneurship, engineering/design or manufacturing. Yet, throughout the years of my career, I have met many people and colleagues who have shared their vision of business and technology, which had a profound effect on me. I really believe those experiences positively impacted my decision to remain in the interdisciplinary field that I’m currently in.

To learn even more about Collin Kobayashi check out the STEM Works article about him, or contact him at info@3d-innovations.com.