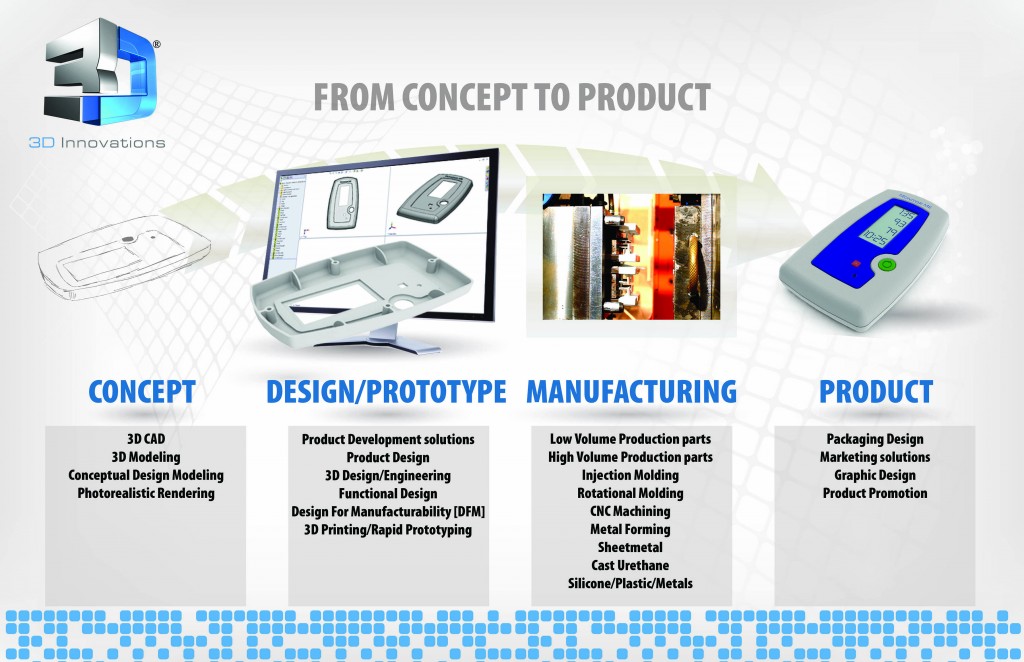

The 3D Innovations Product Development Process Explained

Concept

The conceptual phase typically begins with developing the basic idea and requirements into a visual object that depicts what the final product could look like. This involves integrating industrial design methods that include various materials, surface finish of the parts, and overall aesthetics.

Design/Prototype

With the requirements fully or partially defined, the conceptual design can be transformed into a virtual design that is not only functional, but manufacturable. Design For Manufacturability (DFM) is a critical part of this design phase. The DFM process will be based on the product type and ultimately, the production manufacturing method(s) that will be used. Once a virtual design is completed using 3D CAD (Computer Aided Design), it must be validated to ensure the proper functionality. Having a tangible item to feel, touch, hold, and test is always recommended and can save on the cost of re-design and re-working of production tooling and molds if errors are not caught before proceeding with the manufacturing phase. With 3D Printing becoming more mainstream and with more materials available for use, this is often times the preferred method for prototyping a design. Other prototyping methods can also be used if required. Prototypes can also be produced to be used as marketing tools to present to investors, potential partners, or for media releases.

Manufacturing

Once the design has been fully validated to ensure that form, fit, and function have been accounted for, the production manufacturing phase can begin. If high volume quantities are required, special molds and tooling are likely needed to efficiently and cost effectively produce final production parts. Low volumes can also be produced using various molding methods, but may not be feasible for quantities less than several hundred parts. Depending on the products functionality, an appropriate manufacturing method will be selected. If the product requires integrating electronics or assembly of other parts, this would be done during the manufacturing phase once all individual components have been produced.

Product

Product packaging and marketing play an important role in getting the product launched and promoted in the marketplace. Specialized packaging can be design and manufactured to fit the product specifications. With a team of Marketing and Graphic Design specialists, promotion/marketing, product packaging, graphic design for collateral and websites can be created to showcase the product capabilities.

________

3D Innovations is a full service 3D Engineering/Design company – from the 3D Design to a fully functional 3D Prototype & Product.