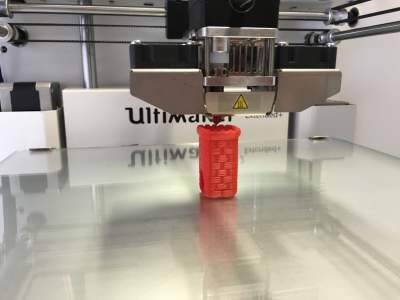

3D printing, also known as additive manufacturing, is one of the most buzzed about technologies of the past five years. The hype around the technology has certainly diminished since its fever pitch in 2014, in which Forbes published, “3-D Printing Is About To Change The World Forever”—and now the genuine potential of the technology is emerging. Certain industries have taken to the technology quicker than others and have been able to successfully implement it into their supply chain. Below we discuss three areas in which 3D printing technology really shines.

Customer Customization

It’s no secret that customers are evolving and their preferences are changing. Where once customers were happy with the “Big Box” store approach, this mentality is starting to shift and customers are looking for more customizable products that meet their specific needs and preferences.

It’s no secret that customers are evolving and their preferences are changing. Where once customers were happy with the “Big Box” store approach, this mentality is starting to shift and customers are looking for more customizable products that meet their specific needs and preferences.

Customization is one of the major benefits of 3D printing. Companies are able to print one-of-a-kind products. One industry that has had great success implementing 3D printing for customization purposes is the designing of prosthetics. Companies and patients have found that they are able to create custom prosthetics at a fraction of the cost with the use of 3D modeling and 3D printing technology.

Designing New Structures

Like anything, traditional manufacturing has its limitations. Until recently certain designs could not be manufactured simply because they were deemed “not possible” or the expense was too exorbitant to be justifiable. However, 3D printing allows for greater design flexibility.

Biomimicry has grown in popularity among product designers and architects, however, these designs are usually manufacturing headaches. “The purpose of biomimicry is to learn from the way nature has optimized structures, designs and objects for maximum performance so that we can use them to create better solutions.” The curvature and delicate nature of the designs are very organic, which poses a challenge when it comes time for production. 3D printing has enabled designers to step out of the traditional way of designing and focus more on what makes the most sense for the product.

Specialty Manufacturing

High variability, low demand products cannot be effectively served by traditional manufacturing methods. If you are a collector of any type of vintage item, then you understand the issues that arise if something breaks or you need to restore a piece. “3-D printing readily solves the challenge of manufacturing rare replacement parts, while also overcoming the obstacle of distribution: a plant exists wherever a printer does.”

Certain components cannot simply be bought, and this is where 3D printing comes into play. With a 3D digital design and a 3D printer, a piece that once was impossible to find can now be produced and put into use in record time.

3D printing technology has found its place in the business landscape. With the continued developments of the technology, it is poised to continue to grow and become even more valuable to businesses.

References:

Lessons Engineers and Architects Should Learn from Nature and Topology Optimization

Four Areas Where 3-D Printing Could Flourish

_______

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Subscribe to the 3D Innovations newsletter on our Facebook page!