3D printing technology and product development go hand-in-hand.

3D printing technology and product development go hand-in-hand.

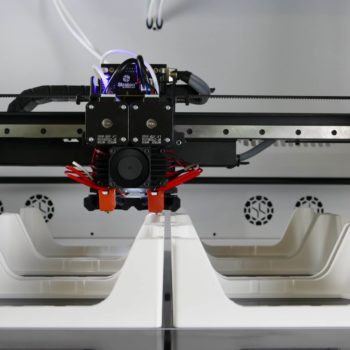

Additive manufacturing, commonly referred to as 3D printing, is a technology that has experienced exponential growth. The rapid acceleration of 3D printing technology advancements, material selection availability and the breakdown of entry barriers, have led to an increased interest by businesses, educational institutions, and governments.

There is a lot of talk about how this technology will revolutionize different facets of life, however, right now, as the technology stands, it truly excels when it comes to assisting with product development. The highly customizable nature of 3D printing means that products can be tailor made to fit different people and situations. Below is a roundup of our recent blog posts related to 3D printing to give you a glimpse into the technology.

Getting Started with 3D Printing

3D printing is one of those technologies that captures the imagination because of the seemingly endless possibilities of it. The ability to fabricate a product on-demand in mere hours, rather than weeks, is a huge reason why entrepreneurs often turn to the technology. We answer the top five questions we frequently receive about the technology in this post.

Using 3D Printing for OEM Replacement Parts

3D printing is a digital technology that has revolutionized OEM replacement parts along with the spare part industry. With product lifecycles becoming shorter and manufacturing advancements happening rapidly, 3D printing has proven itself to be a technology that can stand up to the challenge of producing OEM parts quickly and efficiently.

From 3D Innovations President, Collin Kobayashi, “3D printing is a great solution for producing obsolete parts and can be used for a variety of applications. Understanding the functional requirements will allow the end user or development company to decide which 3D printing method/material is best to meet these functional requirements.”

3D Printing a Prototype: Four Things to Consider

3D printing a prototype is certainly the fastest way to test your product and make the necessary design changes before entering the manufacturing phase of product development.

For years, 3D printing has been synonymous with the prototyping phase of product development. It has not been until recent years that businesses and manufacturers have turned to the technology for end-use parts. While 3D printing technology has rapidly advanced to include new methodology and materials, it is still widely used for product prototyping.

3D Printing: Three Common STL File Errors to Avoid

STL files are a way to transfer the data of your design to the 3D printer in a language the 3D printer will understand. Saving your CAD file in STL file format does not guarantee that you will have a successful print though. As we have mentioned before, 3D printing isn’t a simple push button technology, your STL file needs to be optimized and error free for a successful print.

3D Printing Shines at the Tokyo 2020 Olympics

3D printing excels when it comes to customization and it’s no surprise that it is making a splash and taking center stage, literally, at the Tokyo 2020 Olympics.

Our blog is full of additional 3D printing information and resources if you would like to read more. If you have further questions about the technology or how it can help your business, send us an email at info@3d-innovations.com

_____

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Subscribe to the 3D Innovations newsletter on our Facebook page!