Design for manufacturability (DFM) is a concept that refers to the process of designing products that can be easily and efficiently manufactured. It involves taking into account various factors such as the materials used, production processes, and assembly methods to ensure that the final product is of high quality, cost-effective, and easy to produce.

Design for manufacturability (DFM) is a concept that refers to the process of designing products that can be easily and efficiently manufactured. It involves taking into account various factors such as the materials used, production processes, and assembly methods to ensure that the final product is of high quality, cost-effective, and easy to produce.

DFM is a critical aspect of the product development process, and it can significantly impact a company’s bottom line. By designing products with manufacturability in mind, companies can reduce production costs, shorten lead times, and improve product quality. In this blog post, we’ll explore some of the key considerations that should be taken into account when designing for manufacturability.

In the fast-paced world of manufacturing, where companies strive to deliver innovative products to market quickly, the concept of “Design for Manufacturability” (DFM) has gained significant importance. DFM involves designing products with a focus on optimizing the manufacturing process, minimizing production costs, and ensuring high-quality outcomes. By integrating manufacturing considerations into the design phase, companies can streamline production, reduce waste, and improve overall efficiency. In this blog post, we will explore the key principles and benefits of Design for Manufacturability.

Principles of Design for Manufacturability

- Simplicity and Standardization: A fundamental principle of DFM is to simplify the design and make it as standardized as possible. By reducing the number of components, using standard parts, and minimizing complex features, the manufacturing process becomes more straightforward and efficient. Simplicity also enhances the ability to scale production and reduces the risk of errors during manufacturing.

- Designing for Manufacturing Processes: Designers must have a thorough understanding of the manufacturing processes involved in producing their designs. By considering factors such as material selection, tooling requirements, assembly methods, and production equipment, they can optimize the design to align with the capabilities of the manufacturing process. This approach ensures that the product can be manufactured efficiently and with high quality.

- Designing for Assembly: DFM also encompasses designing for assembly (DFA), which focuses on simplifying the assembly process. Designers should strive to minimize the number of assembly steps, reduce the need for complex tooling, and ensure ease of access for assembly personnel. Well-thought-out DFA improves productivity, reduces assembly time, and minimizes the risk of errors or defects during the assembly process.

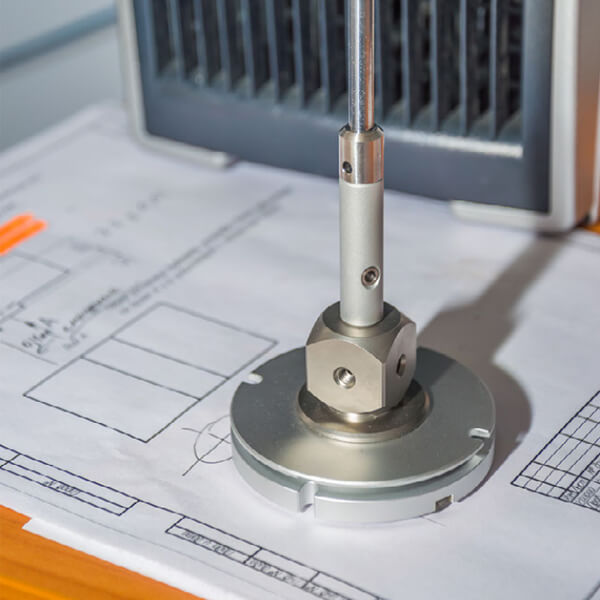

- Prototyping and Testing: Prototyping is an essential step in the DFM process. It allows designers to evaluate the manufacturability of their designs, identify potential issues, and make necessary adjustments early on. By conducting tests and simulations, designers can assess the performance, functionality, and durability of the product, ensuring that it meets the required specifications and can be manufactured reliably.

Benefits of Design for Manufacturability

- Cost Reduction: Implementing DFM principles can lead to significant cost savings. By optimizing the design for efficient manufacturing processes, companies can reduce material waste, minimize the need for rework or repairs, and improve overall production yield. Simplified designs also reduce the number of unique components, enabling bulk purchasing and economies of scale.

- Faster Time-to-Market: DFM helps accelerate the product development cycle by minimizing design iterations and reducing the time required for manufacturing. Early consideration of manufacturing constraints and collaboration between design and manufacturing teams result in smoother transitions from design to production. By reducing lead times, companies can gain a competitive advantage and respond to market demands more effectively.

- Improved Quality and Reliability: Designing with manufacturability in mind increases the likelihood of producing high-quality products. By identifying and addressing potential manufacturing issues during the design phase, companies can prevent defects, reduce scrap rates, and enhance overall product reliability. This approach also improves the consistency of manufacturing processes, resulting in more consistent product performance.

- Enhanced Flexibility and Scalability: DFM promotes scalability and flexibility in manufacturing. By designing products that are easily scalable, companies can respond to changes in demand quickly. Modular designs, standardization, and simplified assembly enable efficient reconfiguration or customization of products, allowing for greater adaptability in a dynamic market.

Conclusion

In conclusion, designing for manufacturability is a critical aspect of the product development process. By considering factors such as material selection, assembly, manufacturing processes, and testing, companies can design products that are easier and more cost-effective to produce. Additionally, designing for manufacturability can help companies improve product quality, reduce lead times, and gain a competitive edge in the marketplace.

Design for Manufacturability is an essential aspect of modern product development. By considering manufacturing constraints from the early stages of design, companies can optimize production processes, reduce costs, and improve overall product quality. The principles of simplicity, standardization, process capability, and material selection guide designers to create products that can be efficiently manufactured at scale. The benefits of DFM, including cost reduction, improved quality, faster time to market, and enhanced customer satisfaction, make it a vital strategy for businesses aiming to succeed in today’s competitive landscape. Embracing DFM can enable companies to unleash their innovative potential and achieve sustainable growth.

With expertise in all areas of Product Development, 3D Innovations can assist with design, prototyping, 3D Printing, Manufacturing, and shipping/logistics. If you’re stuck on deciding which prototype is best, reach out and see how we can assist.

______

Developing Ideas From Concept To Product®

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Connect with us on Twitter, Facebook, Instagram, & LinkedIn today.