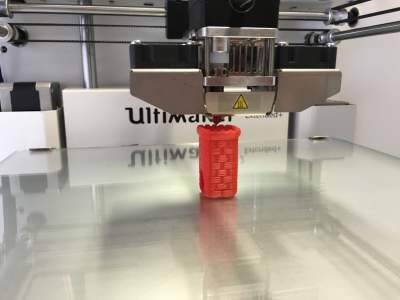

3D printing, also commonly referred to as additive manufacturing, is a technology that has grown exponentially over the last five to ten years. It has been a favorite tool of makers and product design professionals alike. 3D printing technology allows designers to quickly, easily and efficiently design and produce a product prototype for review. While prototyping is where 3D printing is most popular and widely used, the technology is beginning to mature and find it’s way into manufacturing for end-use parts as well.

3D printing, also commonly referred to as additive manufacturing, is a technology that has grown exponentially over the last five to ten years. It has been a favorite tool of makers and product design professionals alike. 3D printing technology allows designers to quickly, easily and efficiently design and produce a product prototype for review. While prototyping is where 3D printing is most popular and widely used, the technology is beginning to mature and find it’s way into manufacturing for end-use parts as well.

Visual Prototyping

“When it was invented, 3D printing was referred to as rapid prototyping, a method for automating and reducing the labor required to create a prototype model for design validation. Since then, it has found use in a number of other applications, but the technology is still widely implemented to create visual models and functional prototypes.”

A visual model of your product lets you get a better idea of how the product will look and feel. With the rapid expansion of 3D printing materials and colors available, you have more options than ever when it comes to product design materials. Most hardware entrepreneurs start with a visual model and then move forward with a functional prototype for design validation and testing.

Functional Prototyping

A functional prototype allows you to test the form, fit and functionality of your product. Testing and validating your product design with a functional prototype is highly recommended so that any potential errors can be fixed before heading into manufacturing.

The benefits of a functional prototype extend beyond your design. With a functional prototype you can also gather critical market feedback, rally financial support from venture capitalists and your community as well as file for a patent.

A major misstep that can derail your hardware startup is to skip the development of a functional prototype.

Tooling

As a design moves from the concept phase to the production phase, a manufacturer might implement 3D printing for the fabrication of custom tools that aid in the production process. “This can include anything from guides for precise drilling, dies for forming or cutting raw material into a specific shape and measurement tools, like gauges, to jigs and fixtures that hold a part in place while other operations are performed.”

3D printing is a flexible tool that can be used either directly or indirectly in the creation of tooling for manufacturing. In the case of indirectly, a tool may be made by coating a 3D-printed component in rubber, which is then used to cast the tool itself.

Production Manufacturing

Currently, due to the speed, quality and cost of 3D printing, “the technology is best suited for the production of specialty parts in smaller batches, rather than mass-manufactured goods. However, there is an industry shift towards expanding 3D printing technology to take a more prominent role in mass manufacturing”.

“3D printing brings some important qualities to the world of manufacturing that make it ideal for certain jobs. For instance, parts can have complex geometries impossible with traditional manufacturing processes. It is also possible to 3D print goods on demand, allowing for easy creation of custom parts.”

Because of these intrinsic benefits, businesses that need to create specialty or custom parts in shorter runs will often turn to 3D printing to manufacture their products. The benefit is that they don’t have to invest in costly tooling to mass produce goods that will only see a limited release.

(Referenced Source: Engineering)

Have additional questions about 3D printing or how the technology can benefit your business? Send us an email at info@3d-innovations.com

_______

3D Innovations is a Product Development Company – from the 3D Design to a fully functional 3D Prototype & Product.

Subscribe to the 3D Innovations newsletter on our Facebook page!